Cone Temperature Chart

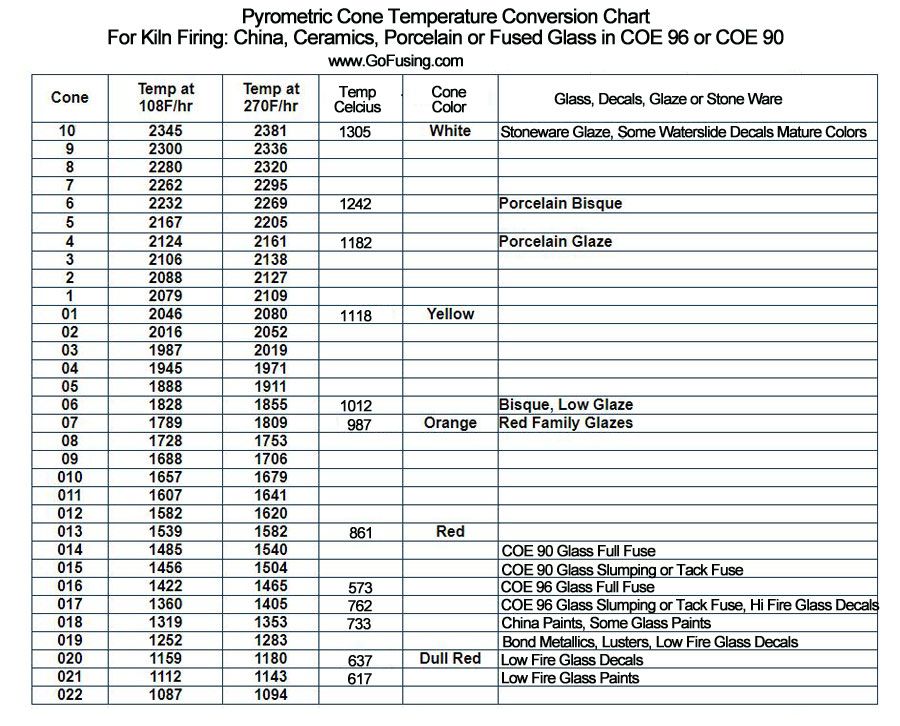

Cone Temperature Chart - Web they measure “heat work” during a firing, or time plus temperature. Keep the chart near your kiln for quick reference. The word cone is often replaced with this symbol overglaze enamels. Fire according to manufacturer instructions. Learn how to use pyrometric cones to measure kiln temperatures for different ceramics bodies. Web cones should be calcined to about 850°f (455°c) in an air atmosphere. Web learn how to use pyrometric cones to monitor and control the firing of ceramics in kilns. (as determined at the national bureau of standards) large cones cone. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. The chart below attempts to do the impossible by assigning a temperature to a cone number. If a cone is soaked at a temperature near its equivalent temperature, it will continue to mature, form glass. Find a pyrometric cone chart, the history of cones in kilns, and tips for cool down control. Web by scrutinizing cone temperature charts, ceramic artists can discern critical details, such as the temperature range at which individual cones begin to bend and. A digital pyrometer can give an accurate temperature, but pyrometric cones are useful for. Web for a proper cone firing, time and temperature must always be considered. Web learn how to use pyrometric cones to monitor and control the firing of ceramics in kilns. Web learn how to use ceramic cones to monitor and control kiln temperatures for different types of clay and glazes. Web cone temperature chart, deg. The rate of increase during the last 300 degrees is the most important. Temperatures shown on the charts were determined. Keep the chart near your kiln for quick reference. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase. See the temperature equivalents for orton. They are useful in determining when a firing is. Fire according to manufacturer instructions. Web learn how to use ceramic cones to monitor and control kiln temperatures for different types of clay and glazes. Web cones should be calcined to about 850°f (455°c) in an air atmosphere. If a cone is soaked at a temperature near its equivalent temperature, it. Web by scrutinizing cone temperature charts, ceramic artists can discern critical details, such as the temperature range at which individual cones begin to bend and. Web they measure “heat work” during a firing, or time plus temperature. Web learn what a cone is and how to use it to fire ceramics. If a cone is soaked at a temperature near. Web learn what a cone is and how to use it to fire ceramics. The rate of increase during the last 300 degrees is the most important. Web for a proper cone firing, time and temperature must always be considered. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered. Each. Web learn how to use pyrometric cones to monitor and control the firing of ceramics in kilns. Web by scrutinizing cone temperature charts, ceramic artists can discern critical details, such as the temperature range at which individual cones begin to bend and. If a cone is soaked at a temperature near its equivalent temperature, it will continue to mature, form. Cones, kilns, glazes and clays vary. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase. They are useful in determining when a firing is. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered. Web learn how to. Web learn how to use pyrometric cones to monitor and control the firing of ceramics in kilns. Fire according to manufacturer instructions. Web learn how to use ceramic cones to monitor and control kiln temperatures for different types of clay and glazes. Web they measure “heat work” during a firing, or time plus temperature. Cones, kilns, glazes and clays vary. Learn how to use pyrometric cones to measure kiln temperatures for different ceramics bodies. Each cone is associated with a range of temperatures, indicating when specific chemical. Web cones should be calcined to about 850°f (455°c) in an air atmosphere. Web this is intended as a general guide. Web generate cone temperature chart and see the conversion between kiln cones. Keep the chart near your kiln for quick reference. (as determined at the national bureau of standards) large cones cone. Web temperature equivalents for ortontm standard pyrometric cones. Web they measure “heat work” during a firing, or time plus temperature. Web this is intended as a general guide. (as determined at the national bureau of standards) large cones cone. Web learn how to use ceramic cones to monitor and control kiln temperatures for different types of clay and glazes. Web the following link contains a chart of temperatures assuming a certain temperature rise. Fire according to manufacturer instructions. Web cones should be calcined to about 850°f (455°c) in. Web cones should be calcined to about 850°f (455°c) in an air atmosphere. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. Find a kiln firing chart in fahrenheit and celsius for each cone nu… They are useful in determining when a firing is. Web the following link contains a chart of temperatures assuming a certain temperature rise. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Fire according to manufacturer instructions. Lusters (metallics and irridescents) all cones mature with time and. If a cone is soaked at a temperature near its equivalent temperature, it will continue to mature, form glass. Web by scrutinizing cone temperature charts, ceramic artists can discern critical details, such as the temperature range at which individual cones begin to bend and. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered. Web they measure “heat work” during a firing, or time plus temperature. The word cone is often replaced with this symbol overglaze enamels. Find a pyrometric cone chart, the history of cones in kilns, and tips for cool down control. Web temperature equivalents for ortontm standard pyrometric cones. Temperatures shown on the charts were determined.Cone 6 Temperature Chart

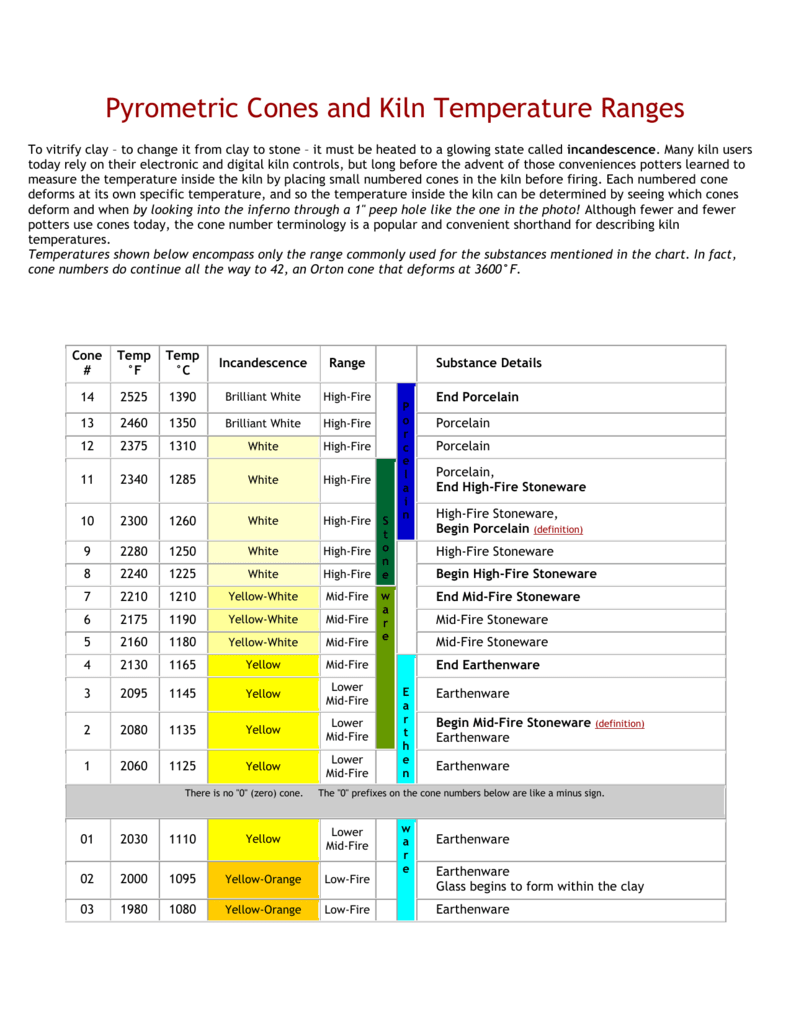

Pyrometric Cones and Kiln Temperature Ranges To vitrify clay to

Pyrometric Cone Temperature Conversion Chart

Kiln Cone Temp Chart A Visual Reference of Charts Chart Master

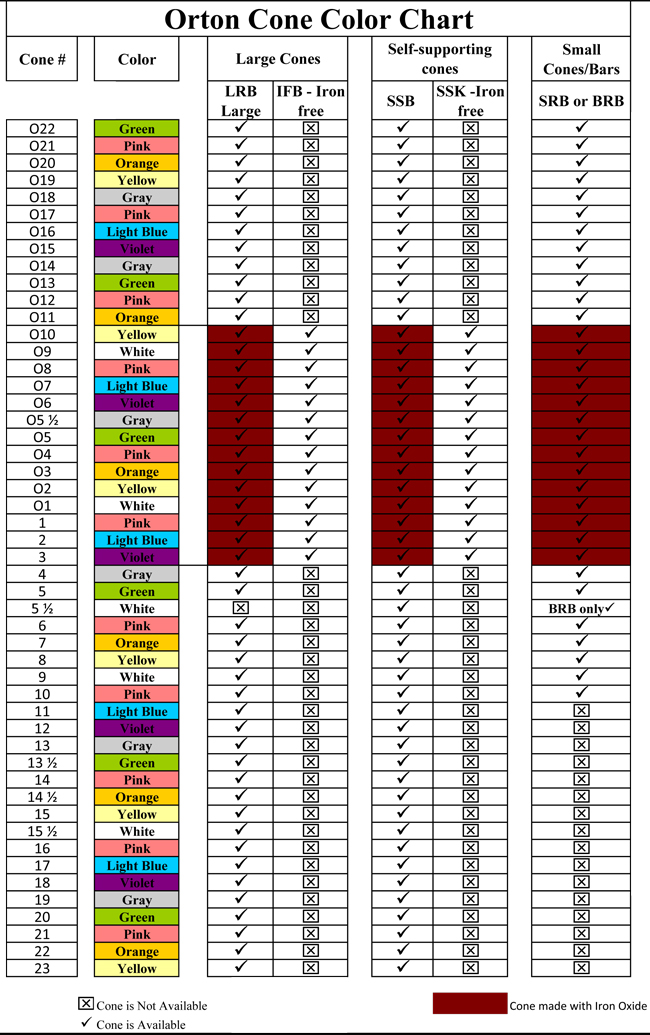

Orton Cone Chart Cone Temperature Chart

Pyrometric Cone Temperature Conversion Chart

Segar Cone Temperature Chart

cone chart Temperature chart, Cones, Cone

Pyrometric Cone Chart for Kiln Firing

Cone 6 Temperature Chart

See The Temperature Equivalents For Orton Cones Based On Different.

Web Generate Cone Temperature Chart And See The Conversion Between Kiln Cones In Fahrenheit And Celsius Based On Selected Heat Rate Increase.

(As Determined At The National Bureau Of Standards) Large Cones Cone.

Web Learn What A Cone Is And How To Use It To Fire Ceramics.

Related Post: