Control Chart Constants

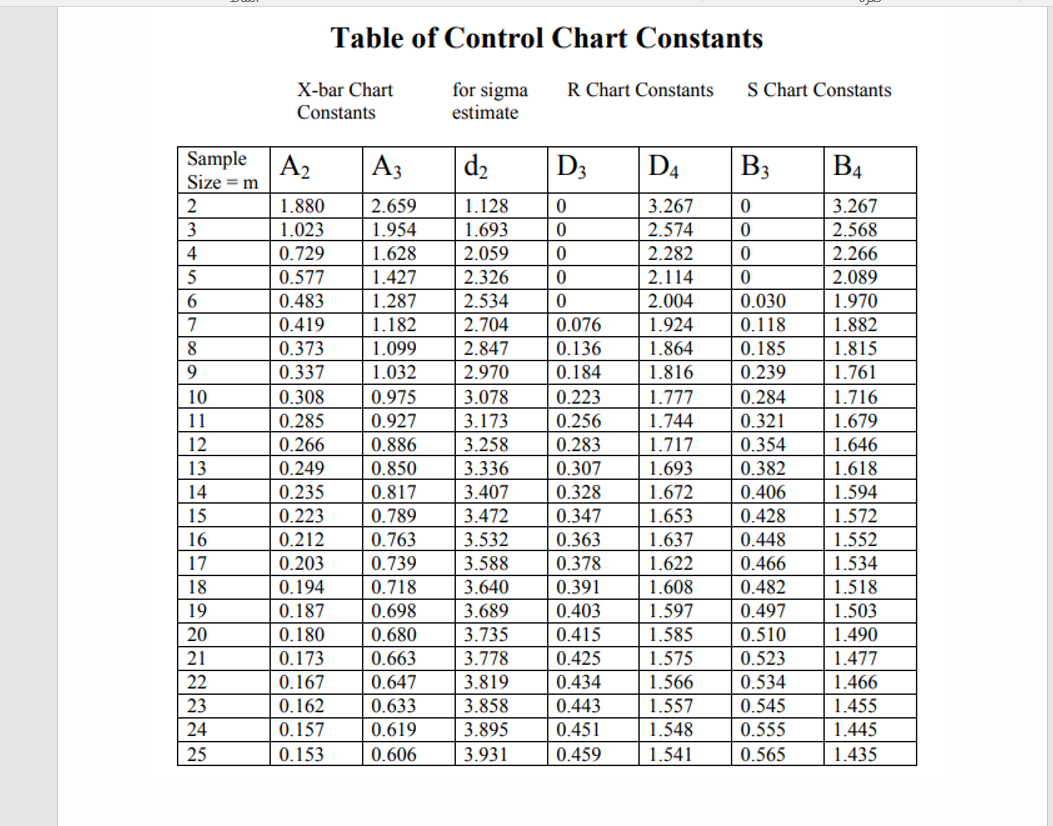

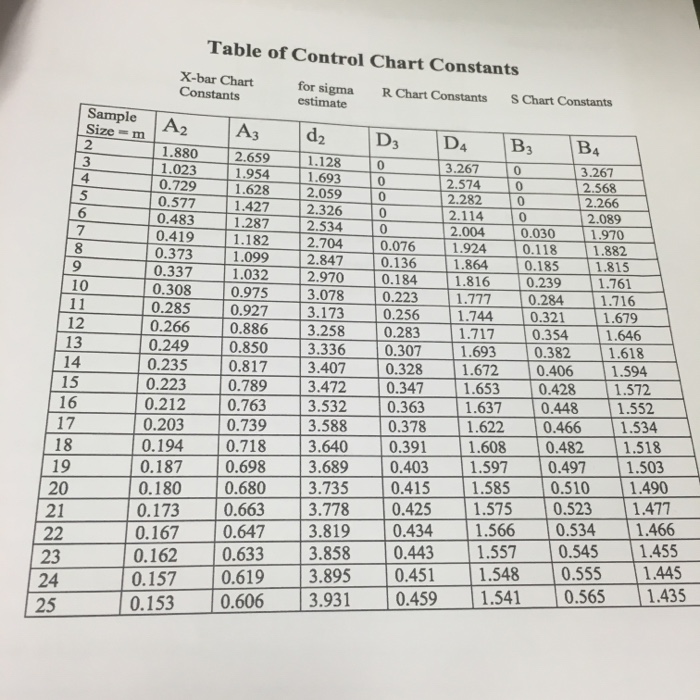

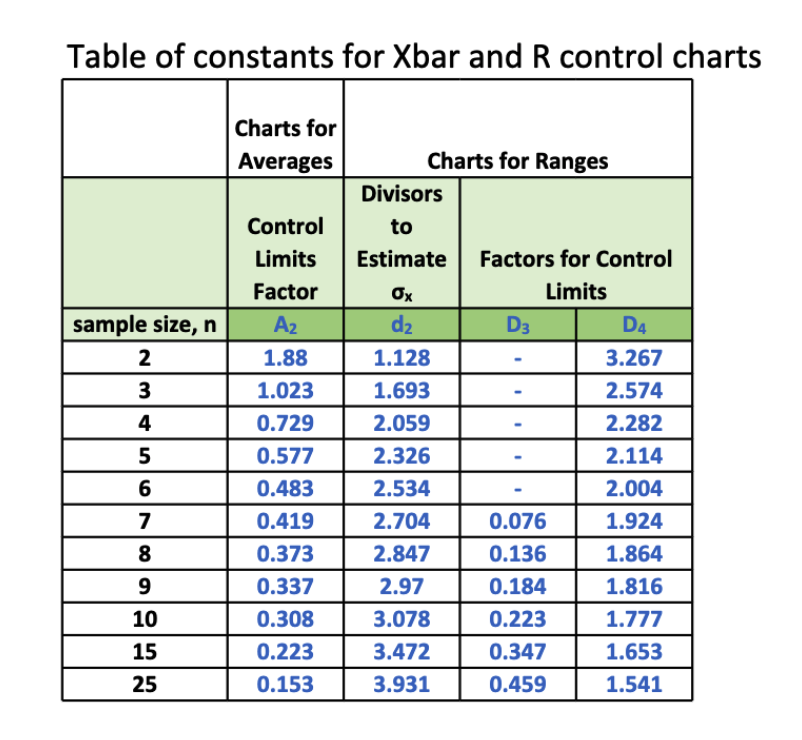

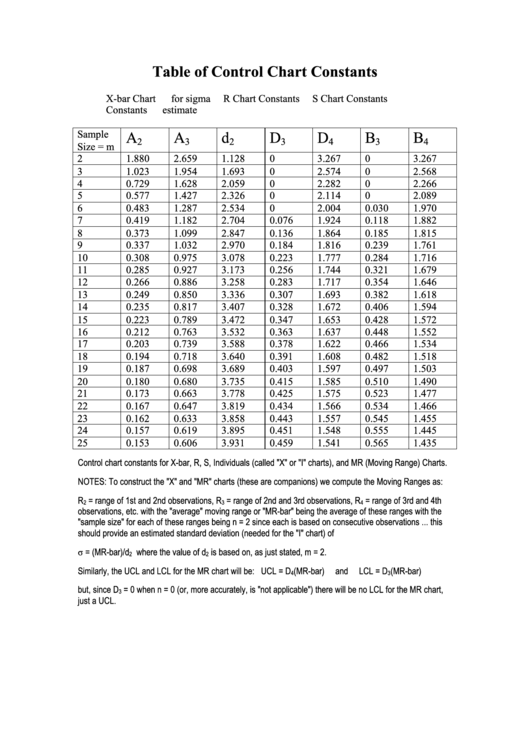

Control Chart Constants - X bar and r charts. Identify the special cause and address the issue. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. But where do the a2 and e2 constants come from? Values for a2, a3, b3, b4, d3, and d4 are all found in a table of control chart constants. Web the x bar chart controls limits that are derived from the r bar (average range) values. Depending on the number of process characteristics to be monitored, there are two basic types of control charts. Web what are variables control charts? Xmr, xbarr, xbars, mr, r, and s type control charts all require these constants to. The value of n is the number of subgroups within each data point. X bar and s charts. Web what are variables control charts? Subgroups falling outside the control limits should be removed from the calculations to. The control chart constants used in the calculations are shown below. Shewhart control charts for variables. Web tables of control chart constants and a brief explanation of how control chart constants are used in different contexts has been presented. Statistical constants are used for both variable control charts like the xmr, xbarr and xands charts and in process capability calculations. Qi macros has the constants built in! Web x ¯ and s shewhart control charts. We begin with x ¯ and s charts. They can help with the following: Web the following formulas are used to compute the upper and lower control limits for statistical process control (spc) charts. Chart for mediams chart for individuals x x sugroup size factors for control Let us consider the case where we have to estimate σ by analyzing past data. X bar and s charts. Xmr, xbarr, xbars, mr, r, and s type control charts all require these constants to. The first, referred to as a univariate control chart, is a graphical display (chart) of. Web the x bar chart controls limits that are derived from the r bar (average range) values. Subgroups falling outside the control limits should be removed from the calculations to.. Predict the range of outcomes for a process. Web control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Table of control chart constants. Assess the effectiveness of a process change. Web what are variables control charts? Qi macros has the constants built in! Web x ¯ and s shewhart control charts. We should use the s chart first to determine if the distribution for the process characteristic is stable. The control chart constants used in the calculations are shown below. Determine the appropriate time period for collecting and plotting data. The value of n is the number of subgroups within each data point. The first, referred to as a univariate control chart, is a graphical display (chart) of. Statistical constants are used for both variable control charts like the xmr, xbarr and xands charts and in process capability calculations. Web control charts can be valuable aids for tracking a continuous. But where do the a2 and e2 constants come from? Continuous/variable control chart table of constants. The value of n is the number of subgroups within each data point. Web control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of the. Web tables of control chart constants and a brief explanation of how control chart constants are used in different contexts has been presented. If the points are out of control in the r chart, then stop the process. Continuous/variable control chart table of constants. Identify the special cause and address the issue. Qi macros has the constants built in! Web the following formulas are used to compute the upper and lower control limits for statistical process control (spc) charts. X bar and r charts. Web control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Web the x bar chart controls limits that are derived from the. If the r chart’s values are out of control, the x bar chart control limits are inaccurate. Choose the appropriate control chart for your data. Web for all practical applications though, especially when you use statistical software applications like minitab, you would note a concept called control chart constants. They can help with the following: But where do the a2. Let us consider the case where we have to estimate σ by analyzing past data. Web control charts are used to routinely monitor quality. X bar and s charts. When one is identified, mark it on the chart and investigate the cause. Statistical methods for six sigma by anand m. But where do the a2 and e2 constants come from? Web control charts are used to routinely monitor quality. When one is identified, mark it on the chart and investigate the cause. If the r chart’s values are out of control, the x bar chart control limits are inaccurate. Choose the appropriate control chart for your data. Predict the range of outcomes for a process. Statistical constants are used for both variable control charts like the xmr, xbarr and xands charts and in process capability calculations. Shewhart proposed a general model for control charts as follows: Web for all practical applications though, especially when you use statistical software applications like minitab, you would note a concept called control chart constants. X bar and s charts. The control chart constants used in the calculations are shown below. Determine whether a process is stable. Web control charts can be valuable aids for tracking a continuous process and gaining insight into a newly established one. Xmr, xbarr, xbars, mr, r, and s type control charts all require these constants to. Web tables of control chart constants and a brief explanation of how control chart constants are used in different contexts has been presented. X bar and s charts.table_of_control_chart_constants_old.pdf Descriptive Statistics

Control Charts Constants for specified pk C value Download Table

Solved Table of Control Chart Constants R Chart Constants S

Control Chart Constants and Formulas.pdf Mathematics Statistical

Tables Of Constants For Control Charts

Control Chart Constants Table

Table Of Control Chart Constants printable pdf download

Control Chart Constants Tables and Brief Explanation RBAR

SOLUTION Control Chart Constants and Formula Studypool

Table Of Control Chart Constants

Web Control Charts Are A Simple Yet Powerful Tool That Helps Us Understand If A Process Is “Stable Or In Control.” Control Charts Are Used In The Control Phase Of The Dmaic (Define, Measure, Analyze, Improve, And Control) Process.

Let Us Consider The Case Where We Have To Estimate Σ By Analyzing Past Data.

They Can Help With The Following:

Web What Are Variables Control Charts?

Related Post: