Copper Tube Od Chart

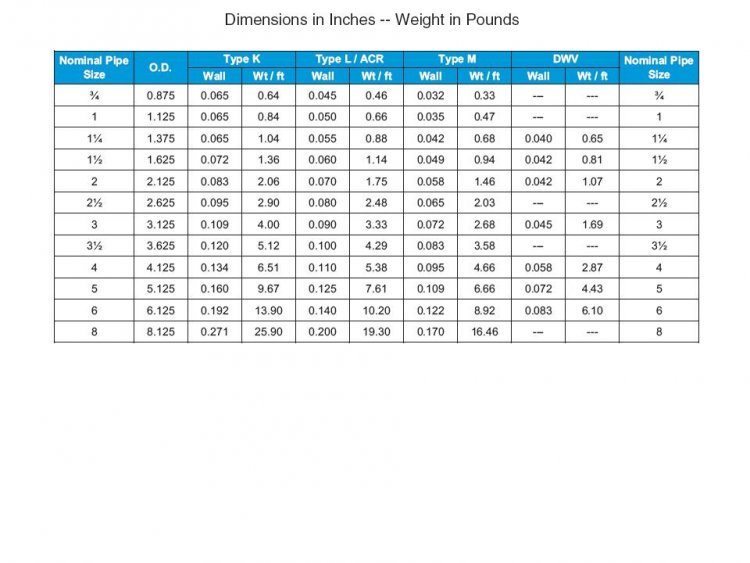

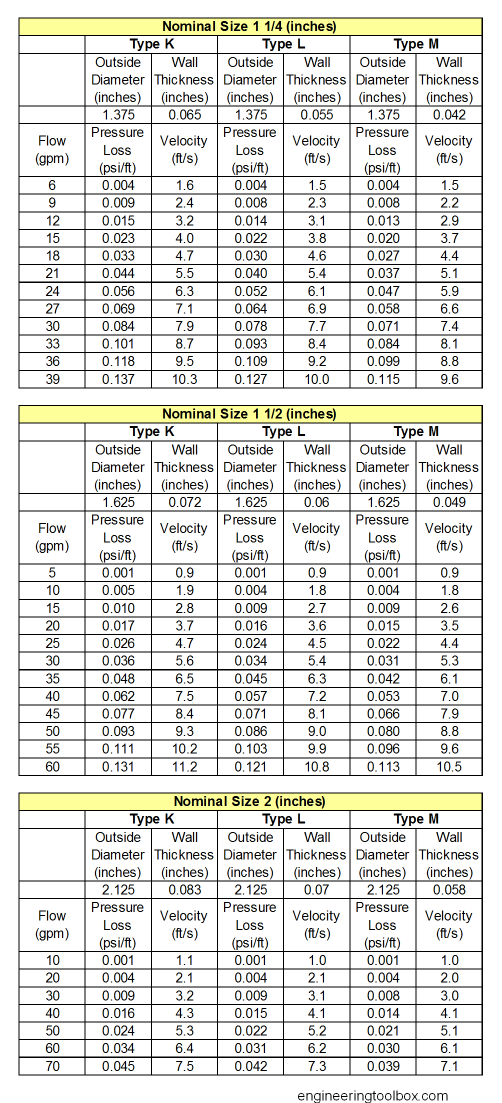

Copper Tube Od Chart - Web the chart shows how the od, id and wall thickness changes as the pipe size increases. Should always be verified before ordering fittings. Web this broad range of flexible tygon ® tubing products are engineered to meet many user specifications including chemical resistance, fluctuations in temperature, abrasion, high purity and long service life. This table lists the outside & inside diameter, wall thickness and internal area for a wide range of commercial pipe sizes. Seamless, round copper tubes for water and gas in sanitary and heating applications. Web copper 0.625 0.75 0.875 1.125 1.375 1.625 2.125 2.625 3.125 3.625 4.125 5.125 6.125 a/c. It also shows working pressure and weight data of different sizes of copper pipe. Our copper tube size chart can help. Web the actual outside diameter (od) of copper pipe is always 1/8 inch larger than the nominal size. Web figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Should always be verified before ordering fittings. Web check out our copper tubing sizes & dimensions chart online at petersen. M, thin walled, above ground residential and light commercial uses. Web this is a copper pipe sizes chart that gives you the approximate inside dimension (id) and wall thickness of copper pipes for 18 nominal pipe sizes (nps) including 3 types k, l, and m. Web this broad range of flexible tygon ® tubing products are engineered to meet many user specifications including chemical resistance, fluctuations in temperature, abrasion, high purity and long service life. Web copper 0.625 0.75 0.875 1.125 1.375 1.625 2.125 2.625 3.125 3.625 4.125 5.125 6.125 a/c. Figure 14.7 brazing flux recommendations. The internal area can be used to calculate velocities of fluids. Web dimensions and physical characteristics of copper tube: Web bending guide for copper tube. Web plastic coated copper tube. Web this is a copper pipe sizes chart that gives you the approximate inside dimension (id) and wall thickness of copper pipes for 18 nominal pipe sizes (nps) including 3 types k, l, and m. Index of tables and figures that represent the supporting technical data. Web dimensions and physical characteristics of copper tube: It. K, thick walled, underground residential, commercial and industrial uses. It is true with all three common types of copper pipe, k, l, and m. Radii of coiled expansion loops and developed lengths of expansion outlets. Guide is furnished for your convenience and is based on the latest pipe standards and information supplied by pipe manufacturers. Web copper 0.625 0.75 0.875. Due to occassional changes and variances in outside diameters, the pipe o.d. Web usa industries nominal tube dimensions chart includes outside diameter, inside diameter, wall thickness and gauge. Web this broad range of flexible tygon ® tubing products are engineered to meet many user specifications including chemical resistance, fluctuations in temperature, abrasion, high purity and long service life. The internal. Due to occasional changes and variances in outside diameters, the pipe o.d. Web the actual outside diameter (od) of copper pipe is always 1/8 inch larger than the nominal size. The internal area can be used to calculate velocities of fluids. Polyethylene coating made from low density ldpe resin and is extruded at 0.025” minimum wall. Web view our helpful. Radii of coiled expansion loops and developed lengths of expansion outlets. Web design specifications for copper tube, tubing types and standards based on astm b88, type k, l, and m size, wall thickness and weight specifications. Web copper 0.625 0.75 0.875 1.125 1.375 1.625 2.125 2.625 3.125 3.625 4.125 5.125 6.125 a/c. M, thin walled, above ground residential and light. Web bending guide for copper tube. Web dimensions of copper water tubing: Web this broad range of flexible tygon ® tubing products are engineered to meet many user specifications including chemical resistance, fluctuations in temperature, abrasion, high purity and long service life. Web copper 0.625 0.75 0.875 1.125 1.375 1.625 2.125 2.625 3.125 3.625 4.125 5.125 6.125 a/c. Seamless, round. Web dimensions and physical characteristics of copper tube: Web bending guide for copper tube. Web view our helpful charts for schedule 40 and standard ips pvc, stainless steel, and brass nipples and piping. Web check out our copper tubing sizes & dimensions chart online at petersen. Due to occasional changes and variances in outside diameters, the pipe o.d. K, thick walled, underground residential, commercial and industrial uses. Web the actual outside diameter (od) of copper pipe is always 1/8 inch larger than the nominal size. Index of tables and figures that represent the supporting technical data. Web dimensions and physical characteristics of copper tube: Guide is furnished for your convenience and is based on the latest pipe standards. Web figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Web this is a copper pipe sizes chart that gives you the approximate inside dimension (id) and wall thickness of copper pipes for 18 nominal pipe sizes (nps) including 3 types k, l, and m. Seamless, round copper tubes for water and. Web dimensions of copper water tubing: Web this broad range of flexible tygon ® tubing products are engineered to meet many user specifications including chemical resistance, fluctuations in temperature, abrasion, high purity and long service life. Me od 3.74 4.64 6.91 9.11 11.24 13.44 15.07 17.15 19.90 22.12 26.48 rb od min 4.00 4.79 7.05 9.22 11.42 13.69 15.40 17.54. M, thin walled, above ground residential and light commercial uses. Web bending guide for copper tube. Index of tables and figures that represent the supporting technical data. Our copper tube size chart can help. Web design specifications for copper tube, tubing types and standards based on astm b88, type k, l, and m size, wall thickness and weight specifications. Guide is furnished for your convenience and is based on the latest pipe standards and information supplied by pipe manufacturers. Me od 3.74 4.64 6.91 9.11 11.24 13.44 15.07 17.15 19.90 22.12 26.48 rb od min 4.00 4.79 7.05 9.22 11.42 13.69 15.40 17.54 20.44 22.50 27.17 rb od max 4.00 5.14 7.40 9.57 11.77 14.04 15.80 17.94 20.44 22. This table lists the outside & inside diameter, wall thickness and internal area for a wide range of commercial pipe sizes. Web dimensions and physical characteristics of copper tube: It also shows working pressure and weight data of different sizes of copper pipe. Web dimensions of copper water tubing: Web the actual outside diameter (od) of copper pipe is always 1/8 inch larger than the nominal size. Guide is furnished for your convenience and is based on the latest pipe standards and information supplied by pipe manufacturers. Web check out our copper tubing sizes & dimensions chart online at petersen. The inside diameter (id) of copper pipe is determined by the wall thickness of the. Figure 14.7 brazing flux recommendations.Copper Pipe ID OD Chart

Copper Pipe Sizing Chart

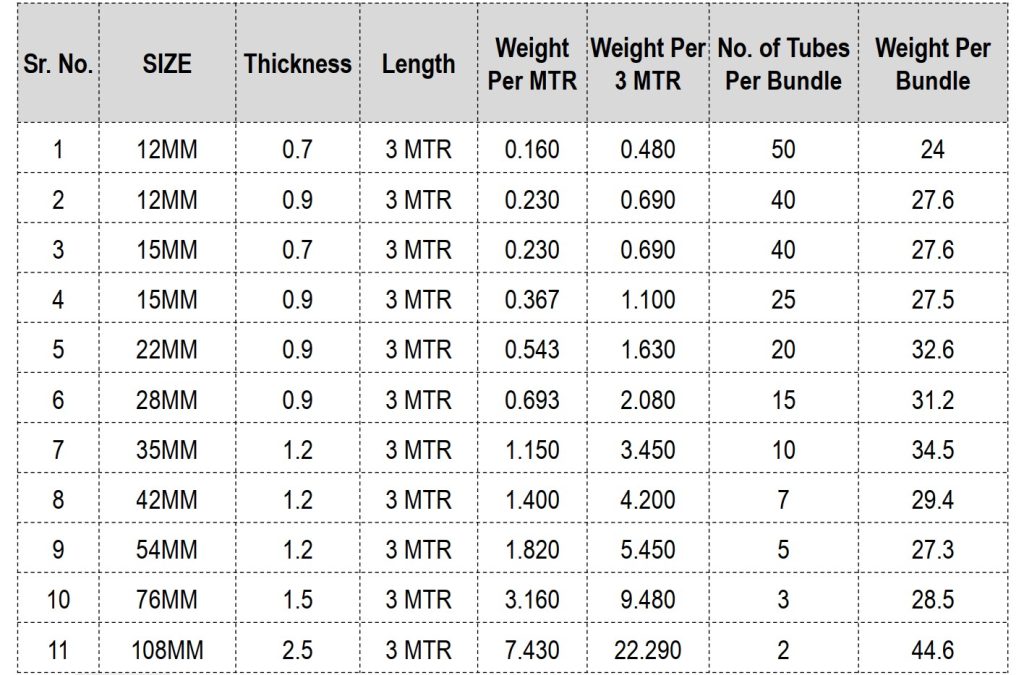

Copper Pipe Size Chart of ASTM B280 Standards by Winland Trading Co

Copper Tubing Wall Thickness Chart

Standard Copper Tubing Size Chart

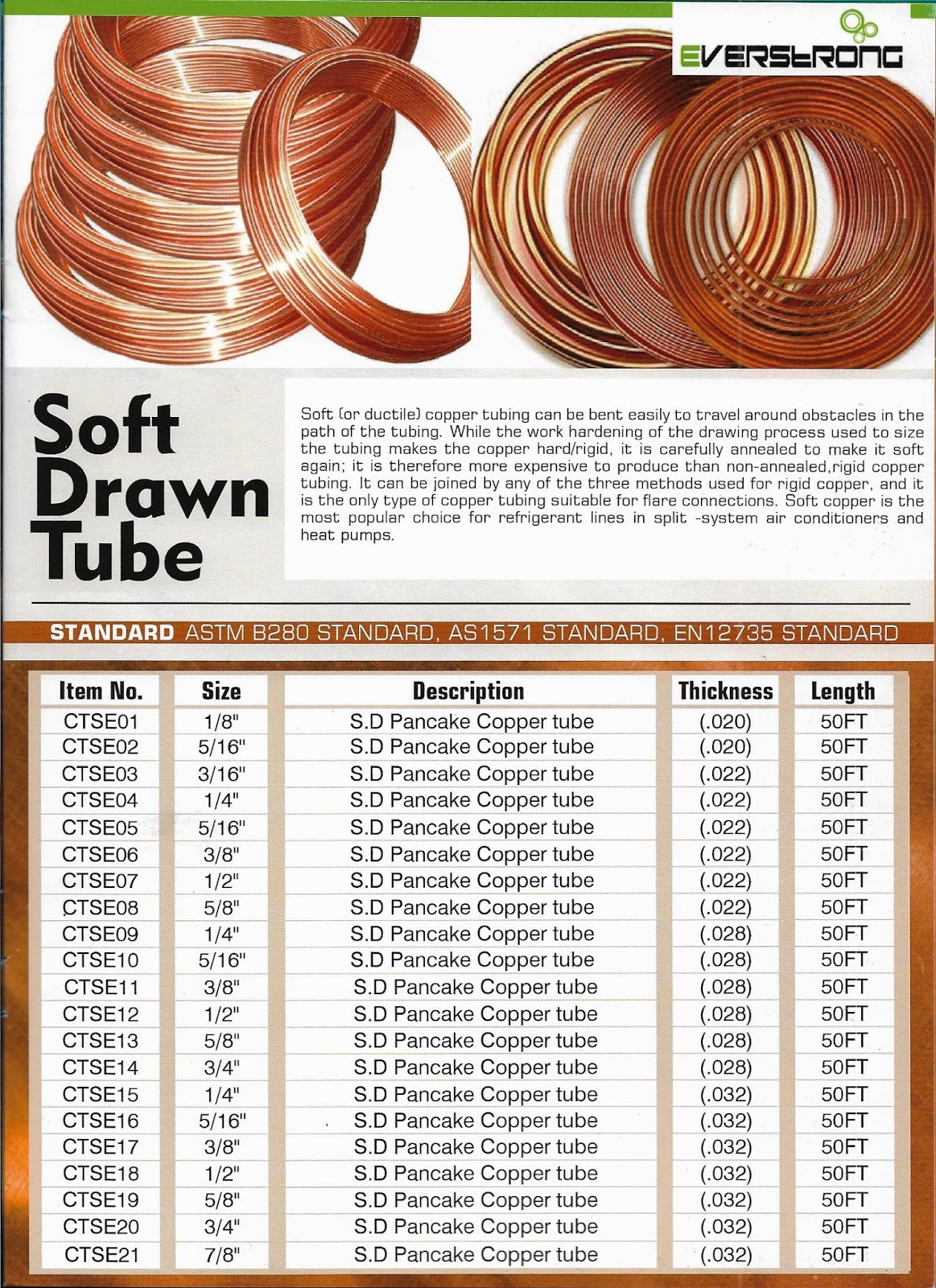

EVERSTRONG COPPER TUBE

Copper Pipe Od Chart

Copper Tubing Sizes Chart

Od Copper Pipe Chart

Copper Pipe Sizes Chart Metric

Polyethylene Coating Made From Low Density Ldpe Resin And Is Extruded At 0.025” Minimum Wall.

It Is True With All Three Common Types Of Copper Pipe, K, L, And M.

Web Usa Industries Nominal Tube Dimensions Chart Includes Outside Diameter, Inside Diameter, Wall Thickness And Gauge.

Web This Broad Range Of Flexible Tygon ® Tubing Products Are Engineered To Meet Many User Specifications Including Chemical Resistance, Fluctuations In Temperature, Abrasion, High Purity And Long Service Life.

Related Post: