Cutting Torch Tips Sizes Charts

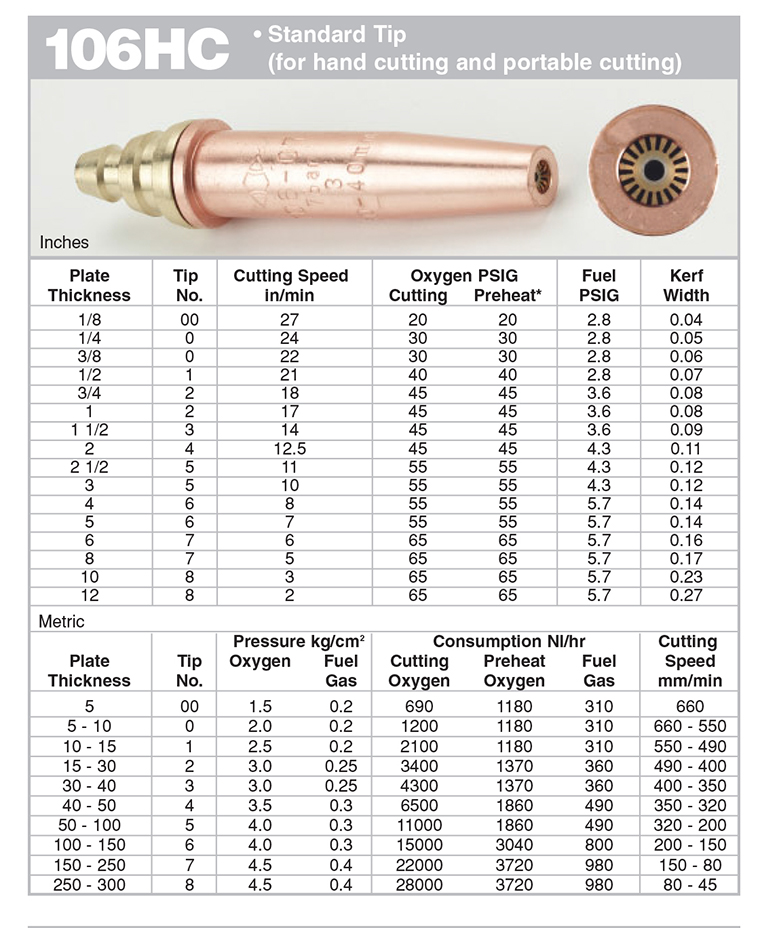

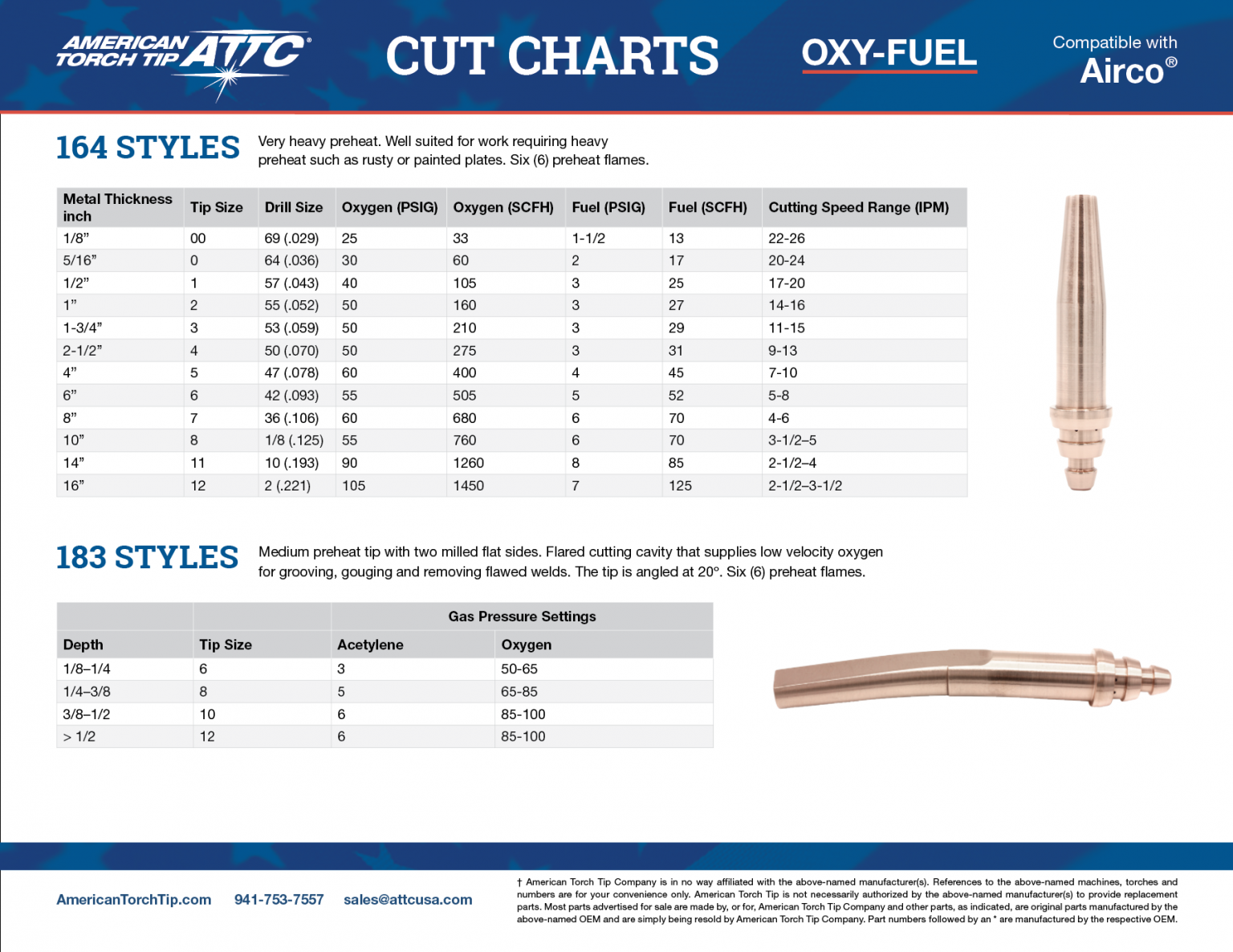

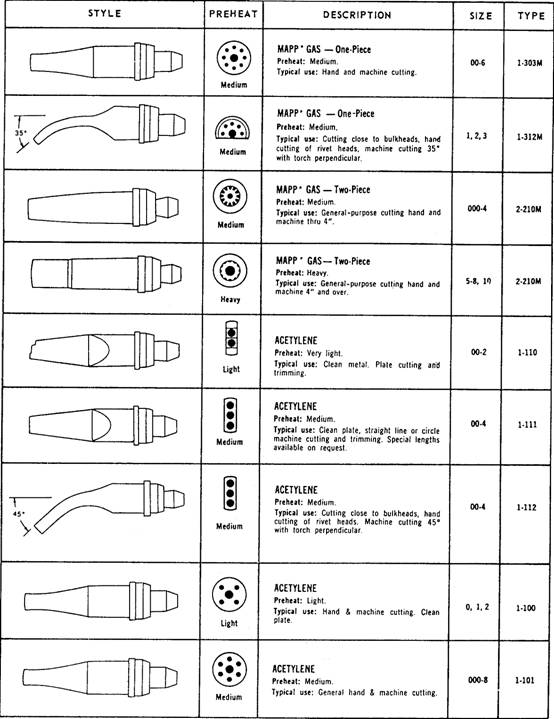

Cutting Torch Tips Sizes Charts - Web use the charts below as recommended settings to use on your regulators for your cutting torch tips. Web st 900fc outfit contents: Other special application tips available. This video covers the variables that impact proper cutting tip selection, including tip seat type,. Over decades, there have been many advances in. Web use this quick and easy guide to help you select the most suitable tip for your smith little torch or silversmith torch. * pressure is measured at the torch inlet on mth series tips. Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate for your cutting setup. Each tip size is suitable for metal thickness as specified in the chart. *** all pressures are measured at the. Other special application tips available. * pressure is measured at the torch inlet on mth series tips. Web the information shown on this page shows series 1 tip style, fuel gas usage and victor equipment compatibility. One being the tip you choose. Web cutting tips come in different sizes so you'll need to look at a chart depending on what thickness metal you will be cutting. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web cutting tip series mthn (high speed machine cutting) notice data compiled using mild steel as test material. Code for fuel gases a acetylene lp propane/natural gas p propylene tip packaging is color coded with reference to fuel gas usage. Web manufactured to meet the most rigid requirements of the metal fabrication industry, prostartm replacement tips are designed to fit the majority of the gas equipment manufacturers’ styles (airco®, harris®, oxweld®, purox®, smith® and victor®), for use in many common and special applications. 350 series regulators with color coded gauges. Web st 900fc outfit contents: Over decades, there have been many advances in. * applicable for three hose machine torch only. Torchs with flashback arrestors require up to 25% more pressure as tip size increases. Web american torch tip cut charts will help you find very specific specs of our different cut chart models and see which one fits your. And answer frequently asked questions about the use of cutting torch tips. One being the tip you choose. Torchs with flashback arrestors require up to 25% more pressure as tip size increases. * applicable for three hose machine torch only. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. Code for fuel gases a acetylene lp propane/natural gas p propylene tip packaging is color coded with reference to fuel gas usage. And answer frequently asked questions about the use of cutting torch tips. One being the tip you choose. Choose from hundreds of tips from radnor™️, victor, harris products group and others perfect for your particular torch size, job. Web below are 2 charts on choosing the correct tip.because not all manufacturers use the same numbering system, the first tip chart shows the hole size you need for the metal thickness you want to cut. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). The thicker the metal, the. Web this article will guide you through choosing the right tips; Web cutting tip series mthn (high speed machine cutting) notice data compiled using mild steel as test material. Using them for optimal performance; Choose from hundreds of tips from radnor™️, victor, harris products group and others perfect for your particular torch size, job needs, cutting material and gas types.. Over decades, there have been many advances in. 350 series regulators with color coded gauges. Web cutting tips come in different sizes so you'll need to look at a chart depending on what thickness metal you will be cutting. Properly maintaining, cleaning, and caring for them; Learn about torch cutting tips here. * pressure is measured at the torch inlet on mth series tips. Web use this quick and easy guide to help you select the most suitable tip for your smith little torch or silversmith torch. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. * applicable for three hose machine torch. * pressure is measured at the torch inlet on mth series tips. Code for fuel gases a acetylene lp propane/natural gas p propylene tip packaging is color coded with reference to fuel gas usage. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. Web cutting tips come in different sizes. Web american torch tip cut charts will help you find very specific specs of our different cut chart models and see which one fits your best needs. 350 series regulators with color coded gauges. Web use the charts below as recommended settings to use on your regulators for your cutting torch tips. Code for fuel gases a acetylene lp propane/natural. Web how to select the correct cutting tips for your oxygen acetylene torch. All pressure settings are flowing pressures. Choose from hundreds of tips from radnor™️, victor, harris products group and others perfect for your particular torch size, job needs, cutting material and gas types. Web below are 2 charts on choosing the correct tip.because not all manufacturers use the. Web how to select the correct cutting tips for your oxygen acetylene torch. Choose from hundreds of tips from radnor™️, victor, harris products group and others perfect for your particular torch size, job needs, cutting material and gas types. Web pressure and flow data: While the selection process may seem daunting there are only 4 main things. Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate for your cutting setup. Torchs with flashback arrestors require up to 25% more pressure as tip size increases. Whether you are buying your first cutting torch or replacing your current one, there are a few things you need to consider in order to get the best one for your project. Cutting data charts are intended as a guide for quality cutting. All pressure settings are flowing pressures. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. Code for fuel gases a acetylene lp propane/natural gas p propylene tip packaging is color coded with reference to fuel gas usage. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). 350 series regulators with color coded gauges. With a two hose cutting torch, preheat pressure is set by the cutting oxygen. Web cutting tips come in different sizes so you'll need to look at a chart depending on what thickness metal you will be cutting. Over decades, there have been many advances in.4 Best Images of Victor Acetylene Cutting Tip Chart Victor Acetylene

Cutting Torch Settings Chart

airco cutting tip chart Bamil

Victor Cutting Torch Tip Chart

Cutting Torch Guide

Airco AFH / AFS Cut Chart American Torch Tip

Propane Cutting Torch Tip Size Chart

Oxy Acetylene Torch Tip Chart

Welding Cut Charts American Torch Tip Cut Charts

Smith Cutting Torch Tip Chart

Web St 900Fc Outfit Contents:

Web American Torch Tip Cut Charts Will Help You Find Very Specific Specs Of Our Different Cut Chart Models And See Which One Fits Your Best Needs.

Web Here We Will Discuss The Various Types Of Cutting Torch Tips And The Best Sizes For Each Job.

Web • Hand And Machine Torch Cutting Data Compiled Using Mild Steel As Test Material.

Related Post: