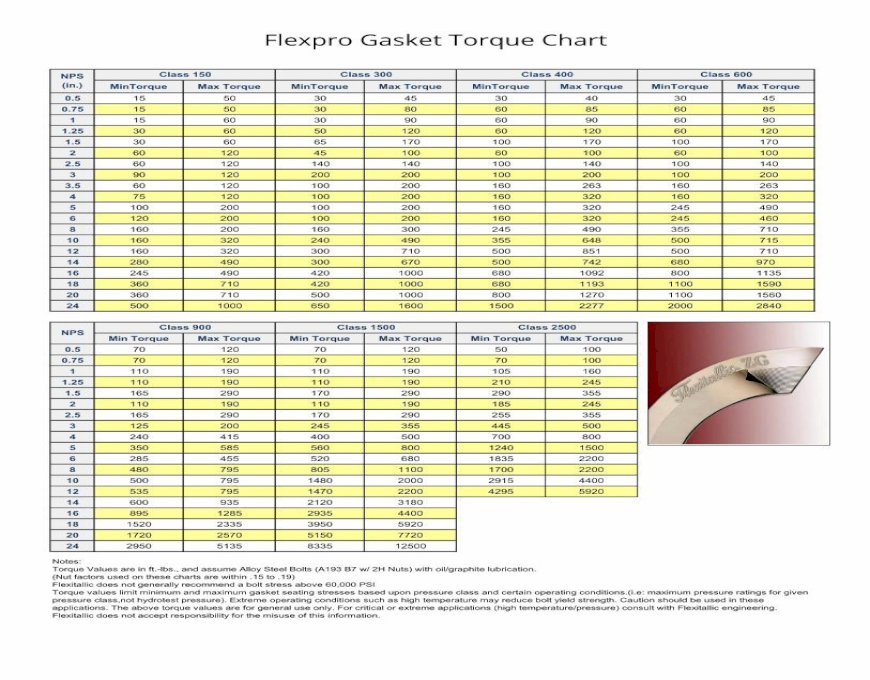

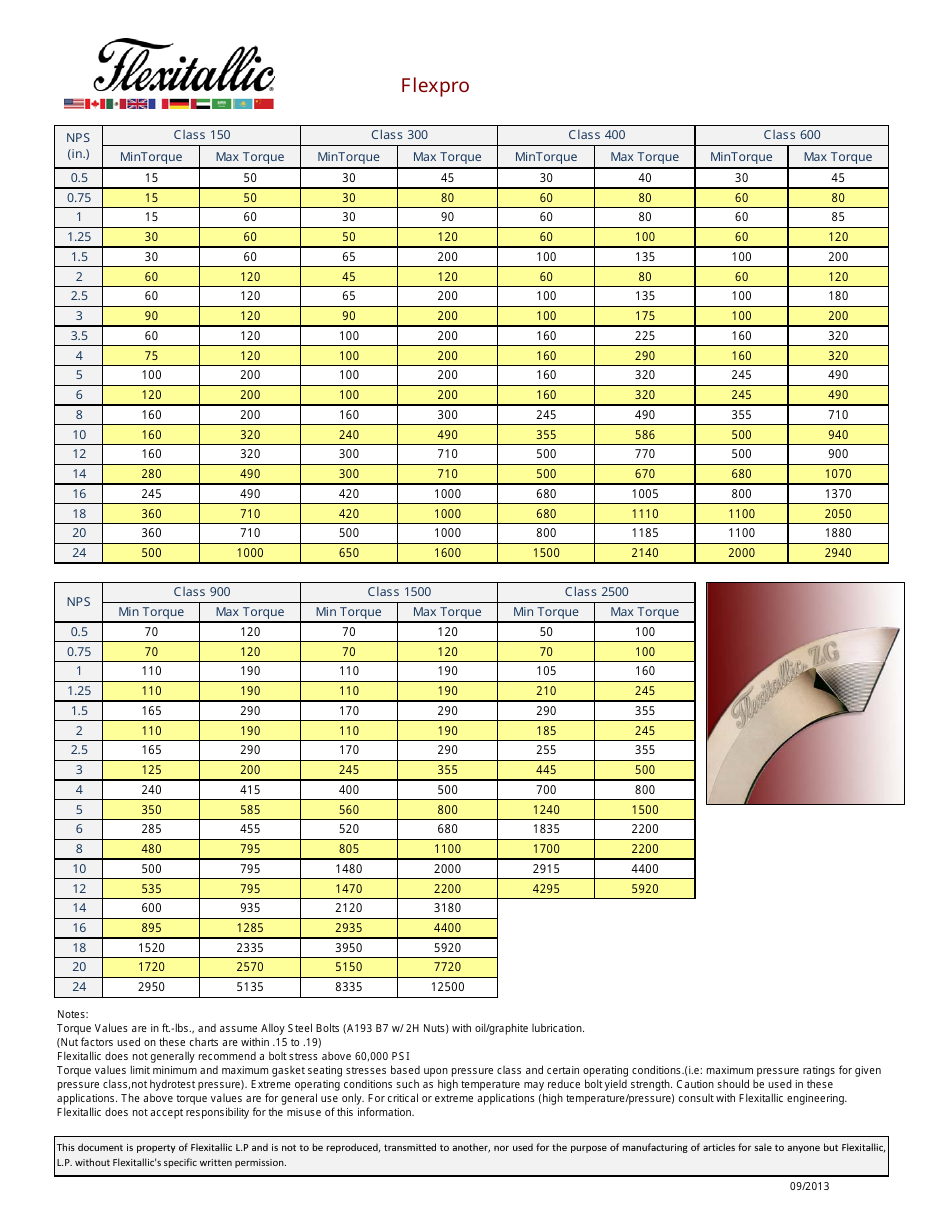

Flexitallic Gasket Torque Chart

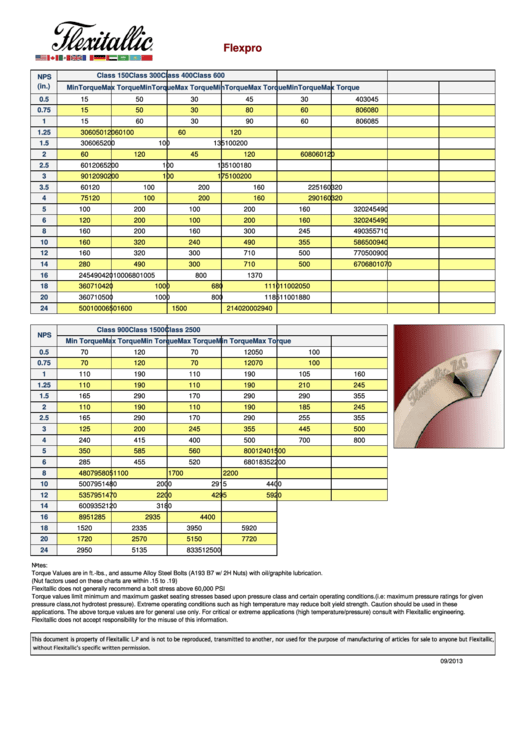

Flexitallic Gasket Torque Chart - Web flexpro gasket torque chart. It provides guidance on the amount of torque required for proper installation and sealing. (nut factors used on these charts are within.15 to.19). Web a torque chart for flexitallic flexpro gaskets is used to determine the recommended torque specifications for installing these gaskets. The product is reinforced with a metal core and is designed for use at temperatures which Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Torque values limit minimum and maximum gasket seating stresses based upon pressure class and Web the flexitallic color code meets the industry standard for metal and filler materials which has been adopted by asme b16.20 and the metallic gasket division of the fluid sealing association. Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Flexitallic does not generally recommend a bolt stress above 60,000 psi. Flexitallic does not generally recommend a bolt stress above 60,000 psi. Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. (nut factors used on these charts are within.15 to.19) (nut factors used on these charts are within.15 to.19). Web flexpro gasket torque chart. Web the flexitallic color code meets the industry standard for metal and filler materials which has been adopted by asme b16.20 and the metallic gasket division of the fluid sealing association. Torque values limit minimum and maximum gasket seating stresses based upon pressure class and Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. It provides guidance on the amount of torque required for proper installation and sealing. The product is reinforced with a metal core and is designed for use at temperatures which (nut factors used on these charts are within.15 to.19). Download torque chart for change gaskets trigger Torque values limit minimum and maximum gasket seating stresses based upon pressure class and (nut factors used on these charts are within.15 to.19) Web a torque chart for flexitallic flexpro gaskets is used to determine the recommended torque specifications for installing these gaskets. Web flexpro gasket torque chart. Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Web torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: Flexitallic does not generally recommend a bolt stress above 60,000 psi. (nut factors used on these. Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. It provides guidance on the amount of torque required for proper installation and sealing. Torque values limit minimum and maximum gasket seating stresses based upon pressure class and Web torque values limit minimum and maximum gasket. (nut factors used on these charts are within.15 to.19) Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. Web torque values limit minimum and. Web torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: (nut factors used on these charts are within.15 to.19) It provides guidance on the amount of torque required for proper installation and sealing. The product is reinforced with a metal core and is designed for use at temperatures which Flexitallic does not. Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. Flexitallic does not generally recommend a bolt stress above 60,000 psi. (nut factors used on these charts are within.15 to.19). Torque values limit minimum and maximum gasket seating stresses based upon pressure class and Maximum pressure. Torque values limit minimum and maximum gasket seating stresses based upon pressure class and (nut factors used on these charts are within.15 to.19). Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature. Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. Web flexpro gasket torque chart. Web the flexitallic color code meets the industry standard for metal and filler materials which has been adopted by asme b16.20 and the metallic gasket division of the fluid sealing association.. Web flexpro gasket torque chart. It provides guidance on the amount of torque required for proper installation and sealing. The product is reinforced with a metal core and is designed for use at temperatures which Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Flexitallic does not generally. Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. (nut factors used on these charts are within.15 to.19). Download torque chart for change gaskets trigger Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield. It provides guidance on the amount of torque required for proper installation and sealing. Web the flexitallic color code meets the industry standard for metal and filler materials which has been adopted by asme b16.20 and the metallic gasket division of the fluid sealing association. Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Web torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: Torque values limit minimum and maximum gasket seating stresses based upon pressure class and Flexitallic does not generally recommend a bolt stress above 60,000 psi. Web flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. Maximum pressure ratings for given pressure class,not hydrotest pressure), extreme operating conditions such as high temperature may reduce bolt yield strength. Web a torque chart for flexitallic flexpro gaskets is used to determine the recommended torque specifications for installing these gaskets. (nut factors used on these charts are within.15 to.19). Web torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: (nut factors used on these charts are within.15 to.19)flexitallic torque chart Penta

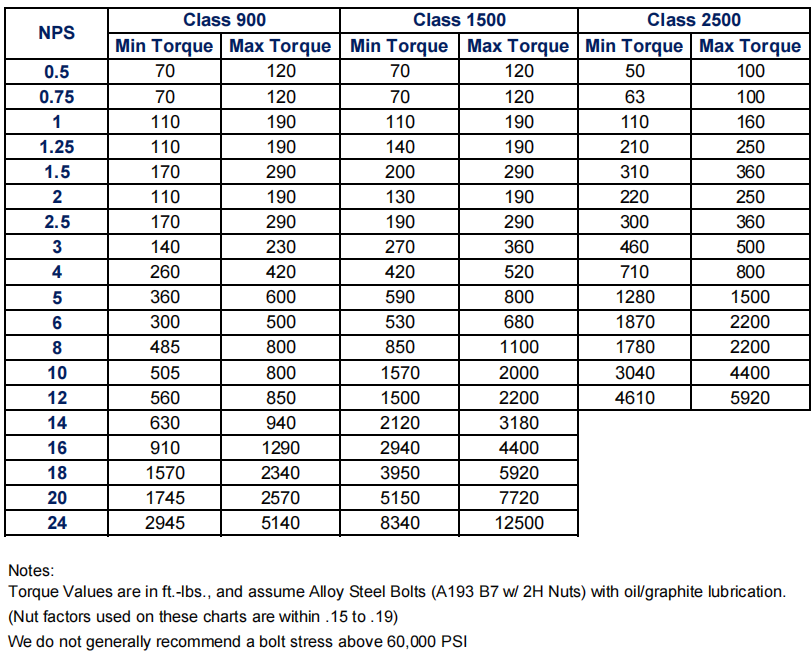

Flexitallic Gasket Torque Chart

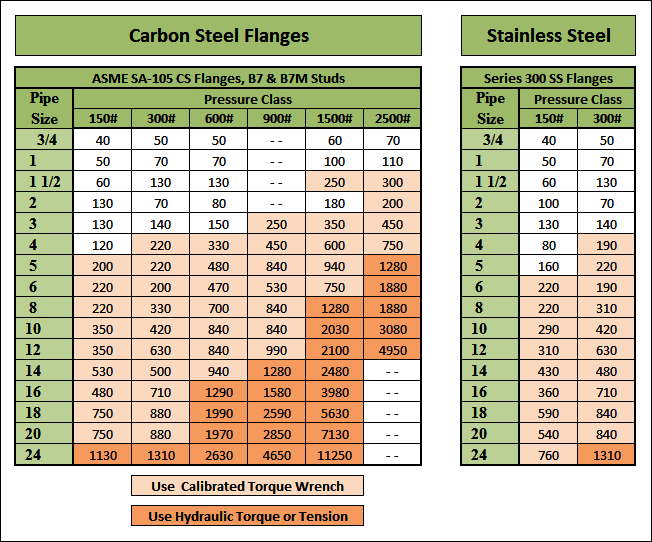

Torque Chart For Change Gaskets Flexitallic, 43 OFF

Flexitallic Gasket Torque Chart

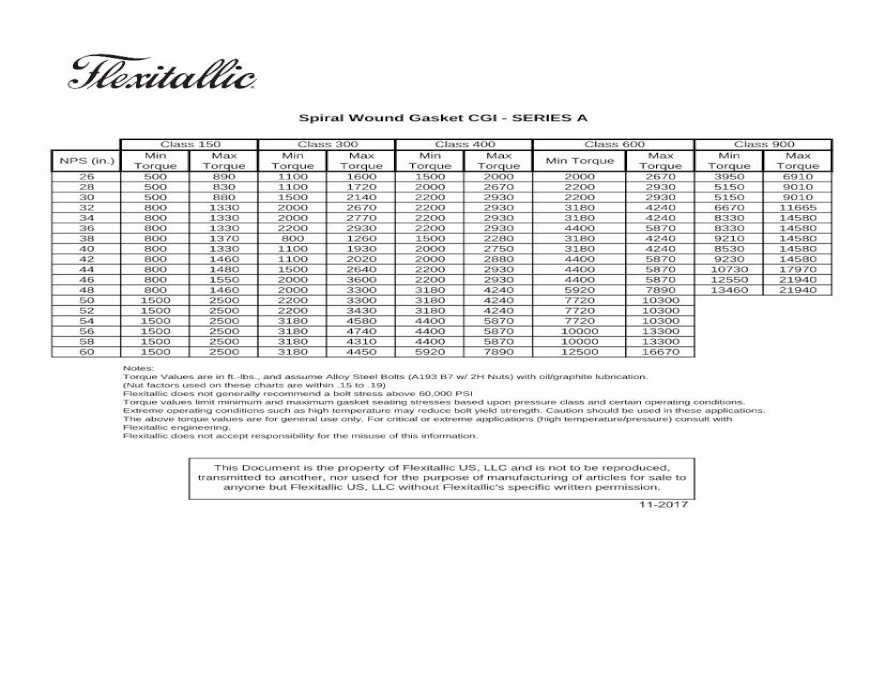

Torque Chart CGI series A Flexitallic USA...Spiral Wound Gasket CGI

Flexitallic Spiral Wound Gaskets Chart

Flexitallic Spiral Wound Gaskets SexiezPicz Web Porn

Flexitallic Gaskets Torque Chart

Flexitallic Torque Chart Flexpro Gaskets Printable Pdf Download Porn

Flexitallic Gaskets Torque Chart

The Product Is Reinforced With A Metal Core And Is Designed For Use At Temperatures Which

Web Flexpro Gasket Torque Chart.

Download Torque Chart For Change Gaskets Trigger

Related Post: