K Factor Chart

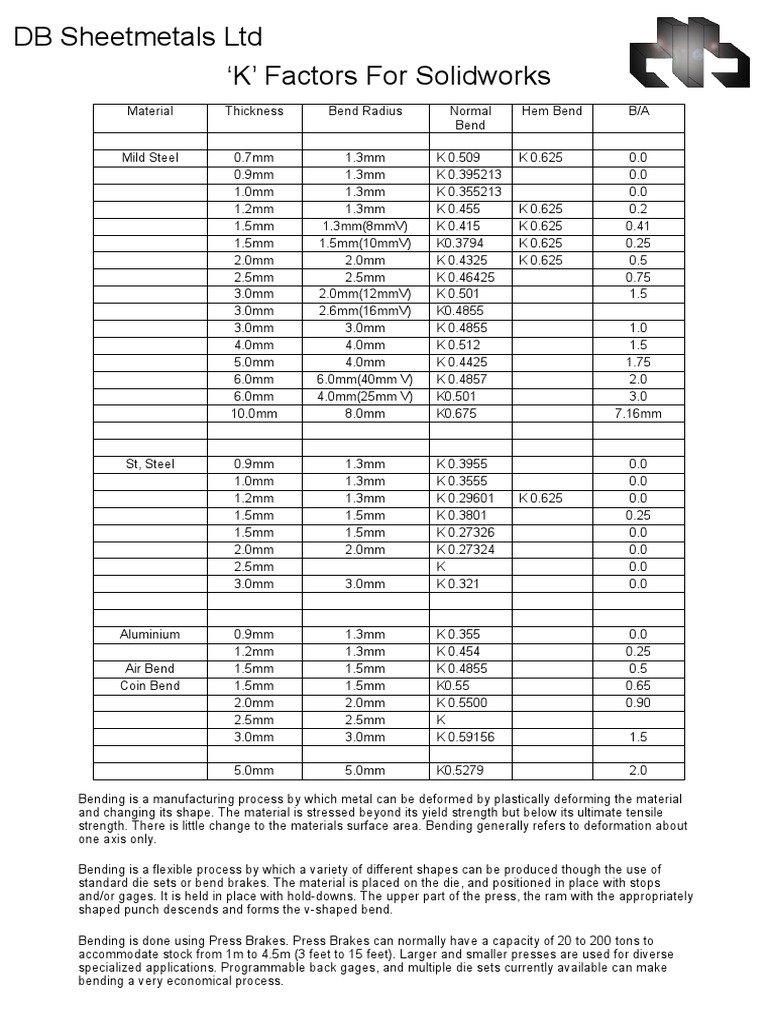

K Factor Chart - To calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. Metric calculations use the flow in liters per minute and pressure in bar. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Web how to calculate bend allowance, k factor and y coefficient in one click. The calculator returns the answer as a decimal. Also, find our k factor calculator for the bend radius formula here. Web k factor is an empirical constant, meaning that its value was determined by testing. In fact, it varies according to the type of material to be deformed. Web solidworks sheet metal tools are relatively straight forward, but may not be clearly understood. Web the experts at fma provide q deep dive into the k factor, what it is, and why it matters. The calculator returns the answer as a decimal. It is also used independently to calculate the bend allowance (ba) under various conditions, such as: It varies according to material, its thickness, bend radius and bending method. Also, find our k factor calculator for the bend radius formula here. Web online bend deduction calculator. You can also use our flat pattern calculator for blank size calculation. In fact, it varies according to the type of material to be deformed. Web k factor is an empirical constant, meaning that its value was determined by testing. It’s calculated in imperial units for the united states by using the flow in gallons per minute (gpm) and the pressure in psi. To calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. Read the bend allowance and deduction from the last two fields. Web online bend deduction calculator. Web how to calculate bend allowance, k factor and y coefficient in one click. Generally, a normal range of 0 to.5 is seen in the case of standard material and thicknesses. Web the k factor calculator uses the thickness of the material, bend angle,. It’s calculated in imperial units for the united states by using the flow in gallons per minute (gpm) and the pressure in psi. The chart will be posted soon… Metric calculations use the flow in liters per minute and pressure in bar. Learn about them to avoid issues during your design process. It varies according to material, its thickness, bend. To calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. In fact, it varies according to the type of material to be deformed. Web k factor is an empirical constant, meaning that its value was determined by testing. Learn. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. To calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. Web mathematically k factor value is equal to the. The chart will be posted soon… To calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. Also, find our k factor calculator for the bend radius formula here. It is important to predict the bending allowance, which is the. The chart will be posted soon… Web the experts at fma provide q deep dive into the k factor, what it is, and why it matters. Learn about them to avoid issues during your design process. Choose units and enter the following: It is important to predict the bending allowance, which is the amount of material needed to achieve a. Metric calculations use the flow in liters per minute and pressure in bar. You can also use our flat pattern calculator for blank size calculation. The chart will be posted soon… Web solidworks sheet metal tools are relatively straight forward, but may not be clearly understood. Choose units and enter the following: The calculator returns the answer as a decimal. Basically, the k factor offsets the neutral line to provide a flat pattern that reflects reality. Web the k factor calculator uses the thickness of the material, bend angle, inside radius, and bend allowance to find the k factor. Read the bend allowance and deduction from the last two fields. In fact,. Web k factor is an empirical constant, meaning that its value was determined by testing. It’s calculated in imperial units for the united states by using the flow in gallons per minute (gpm) and the pressure in psi. It ultimately allows you to estimate the amount of stretch without knowing what type of material you are bending. Choose units and. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. It varies according to material, its thickness, bend radius and bending method. Web solidworks sheet metal tools are relatively straight forward, but may not be clearly understood. You can also use our flat pattern calculator for blank size calculation. The. Metric calculations use the flow in liters per minute and pressure in bar. Web k factor is an empirical constant, meaning that its value was determined by testing. Read the bend allowance and deduction from the last two fields. Web how to calculate bend allowance, k factor and y coefficient in one click. Learn about them to avoid issues during your design process. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Web solidworks sheet metal tools are relatively straight forward, but may not be clearly understood. Web the experts at fma provide q deep dive into the k factor, what it is, and why it matters. To calculate the bend allowance, the k factor and the derived coefficient called the y factor, insert the thickness and initial length of the sheet into the cells on the left. You can also use our flat pattern calculator for blank size calculation. It varies according to material, its thickness, bend radius and bending method. Web the k factor calculator uses the thickness of the material, bend angle, inside radius, and bend allowance to find the k factor. Choose units and enter the following: Web mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. By understanding these principles, you can improve the precision and efficiency of your sheet metal projects. The chart will be posted soon…K Factor Quick Reference Thermo Scientific Home Page

K Factor Table Statistics Elcho Table

Soil erodibility (K) factor values Download Table

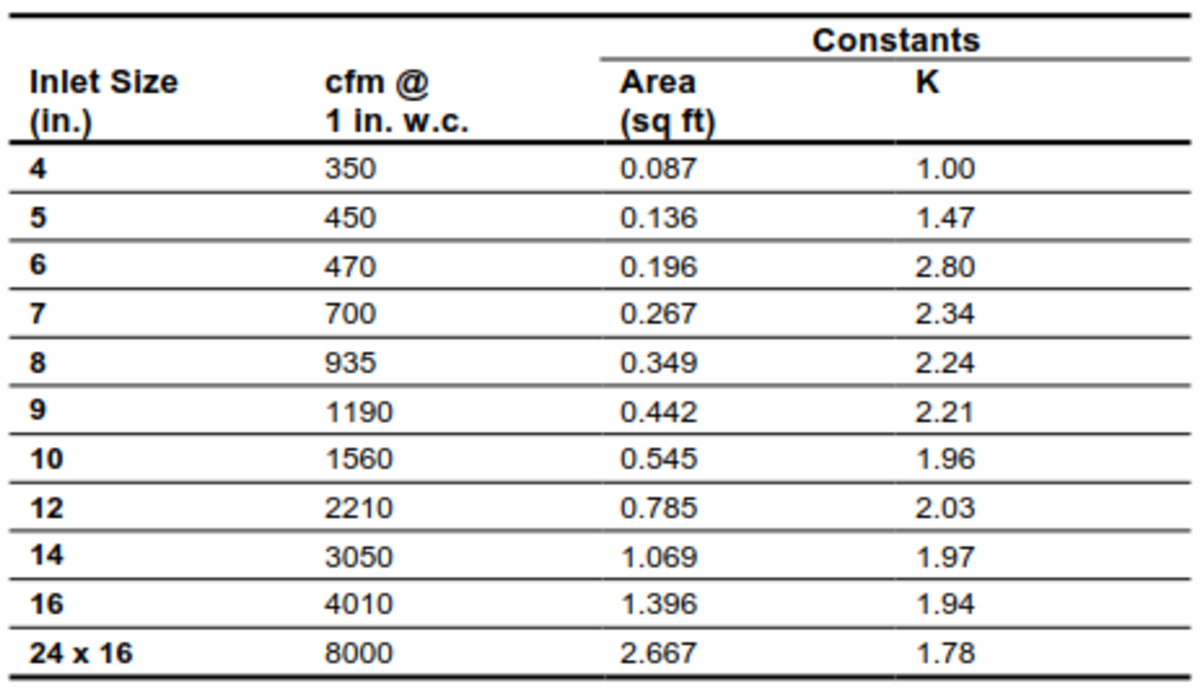

What is the K factor and how do we use it in HVAC applications? Hvac

K Factors + Bending Info Sheet Metal Industries

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory

What Is K Factor Reference Chart From Agf Manufacturi vrogue.co

Analyzing the kfactor in sheet metal bending Part II

Kfactor & Transformers Power Quality Blog

What is KFactor? Reference Chart from AGF Manufacturing

It’s Calculated In Imperial Units For The United States By Using The Flow In Gallons Per Minute (Gpm) And The Pressure In Psi.

It Ultimately Allows You To Estimate The Amount Of Stretch Without Knowing What Type Of Material You Are Bending.

Web Online Bend Deduction Calculator.

Generally, A Normal Range Of 0 To.5 Is Seen In The Case Of Standard Material And Thicknesses.

Related Post: