Tapcon Drill Bit Sizes Chart

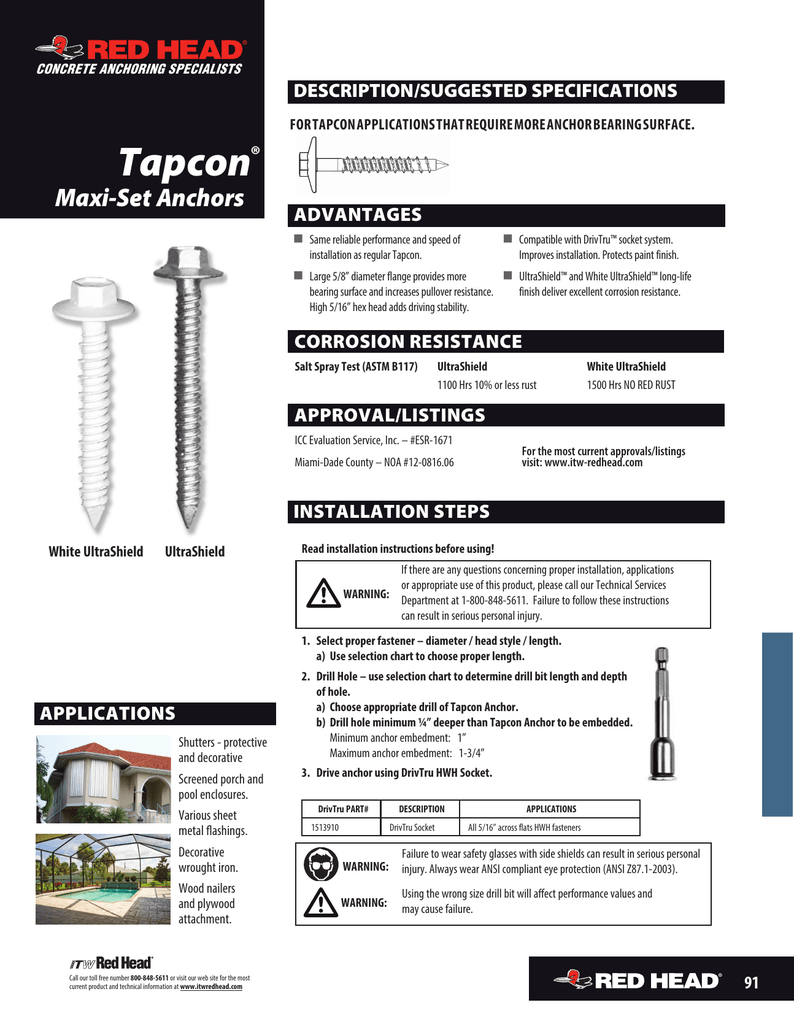

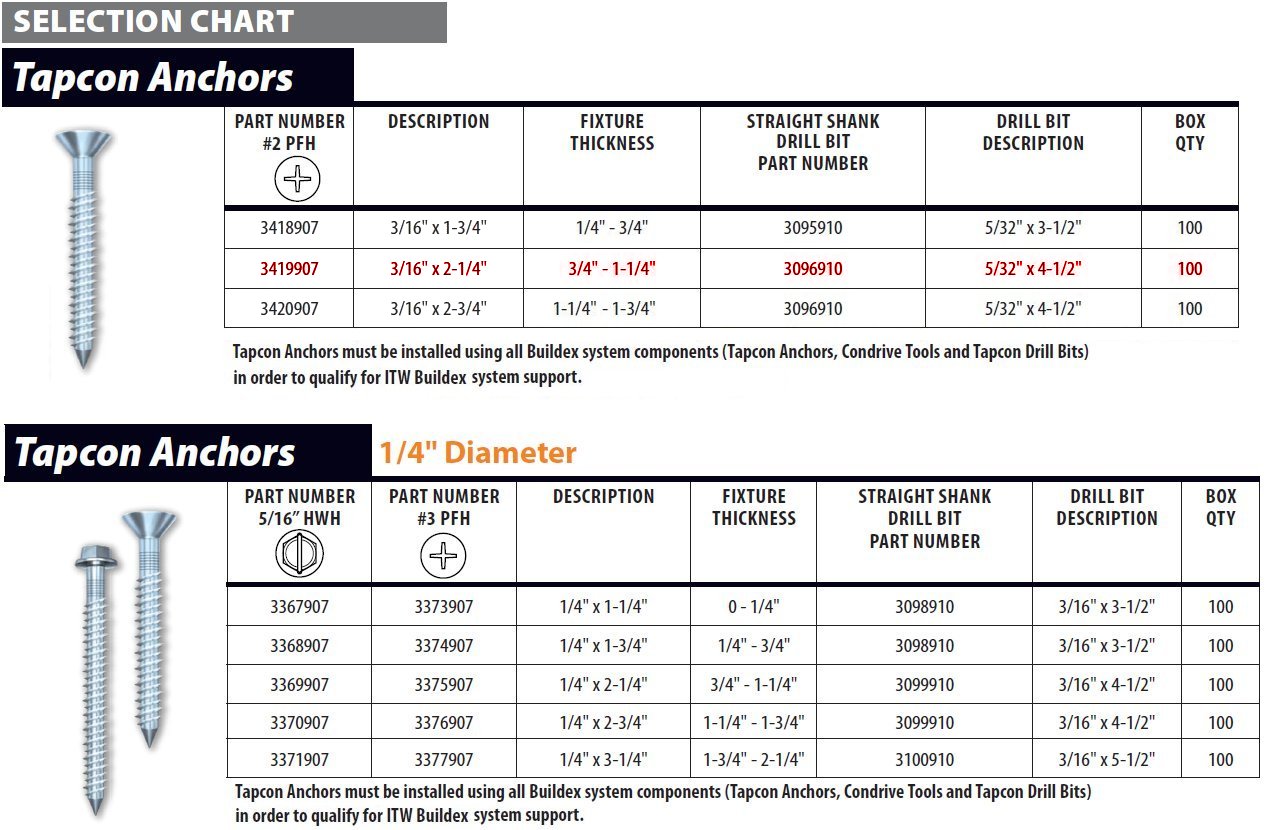

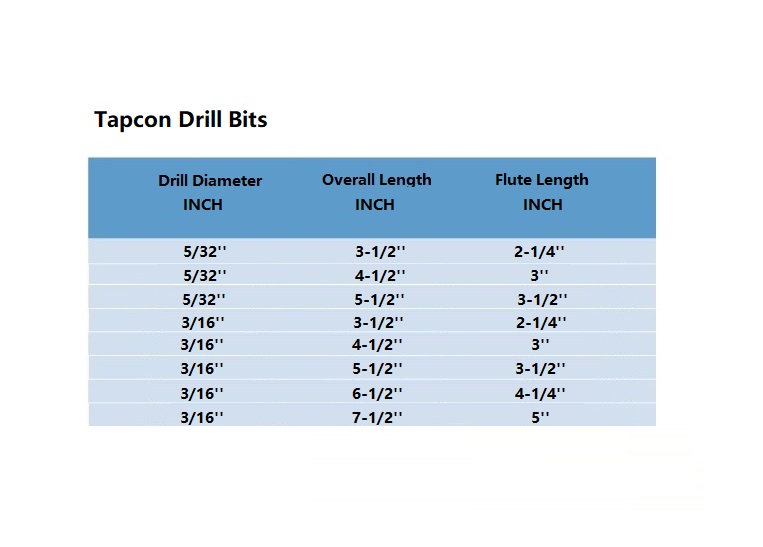

Tapcon Drill Bit Sizes Chart - These two dimensions should match the tapcon size in order to achieve the required holding values. There are multiple drill bit alternatives to use for different materials or to serve a different purpose. This is key for a secure fit. Eliminates the need for two drills or extra nut drivers. Also, consider the length of the tapcon screw when selecting a drill bit. Web in our guide, you can use our tapcon drill bit size chart to get the right tapcon drill bit size. Use the tapcon bits and condrive pro together to install tapcon anchors for optimal performance. Tension strength design information for tapcon+ screw anchors1. Web the ideal drill bit size for a 5/16″ tapcon is generally a 1/4″ bit. Installation information for tapcon+ screw anchors1. These two dimensions should match the tapcon size in order to achieve the required holding values. A sds shank tapcon drill bit can be expected to drill 100 holes minimum to full depth in 4,000 psi concrete. Web makes installation of tapcon® concrete anchors easy, fast, and accurate. Tension strength design information for tapcon+ screw anchors1. Installs both head styles and all lengths of tapcons. Using an electric impact wrench, or socket wrench (hand install) insert anchor into hole and tighten anchor until fully seated. (see chart for socket size) (do not over tighten). Tapcon® is a registered trademark of buildex, a divison of illinois tool works, inc. By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an accurate fit, thus obtaining higher tolerances for your concrete anchors. Installation information for tapcon+ screw anchors1. Excellent for wood to concrete applications. Designed for use with a hammer drill and tapcon drill bits. There are numerous technical specifications that must be considered when using tapcon® screws. Select a length that meets your application needs. Web when it comes to 3/8 tapcons, consider the drill bit size. This size ensures a snug fit for the screw, allowing it to grip the masonry effectively and provide optimum holding power. Web our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power. These two dimensions should match the tapcon size in order to. The standard drill bit is universally used for drilling smaller pilot holes in concrete, block and brick, and works seamlessly with tapcon anchors. Web makes installation of tapcon® concrete anchors easy, fast, and accurate. Web view detailed information about drill bits for tapcon cement screw anchors, sizes, length and where to purchase. N installs in less than half the time. Using an electric impact wrench, or socket wrench (hand install) insert anchor into hole and tighten anchor until fully seated. Variations in the drill bit size can affect the efficiency of the screw’s installation and the strength of its hold. N single piece design—no nut and washer assembly. Check the packaging or manufacturer’s instructions for more details. Tool drives 3/16”. A straight shank tapcon drill bit can be expected to drill 60 holes minimum to a 2 depth in 4,000 psi concrete. Web find one with bits suited to different materials and in a variety of sizes. (see chart for socket size) (do not over tighten). Secure the drill bit in the power drill and make sure it’s aligned and. Drill bits for drilling wood, plastic, tile, and metal are available in sets or individually. A sds shank tapcon drill bit can be expected to drill 100 holes minimum to full depth in 4,000 psi concrete. Tension strength design information for tapcon+ screw anchors1. (see chart for socket size) (do not over tighten). Web makes installation of tapcon® concrete anchors. Excellent for wood to concrete applications. Before using the products, all specifications and calculations must be checked by a suitably qualified person and local regulations must be observed. (see chart for socket size) (do not over tighten). Web tapcon concrete screw technical specifications and information. Web when it comes to 3/8 tapcons, consider the drill bit size. After setup, each tapcon screw must meet the required embedment depth. Using a socket wrench insert anchor into hole Web view detailed information about drill bits for tapcon cement screw anchors, sizes, length and where to purchase. By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an. (see chart for socket size) (do not over tighten). Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. Secure the drill bit in the power drill and make sure it’s aligned and tight. Also, consider the. A sds shank tapcon drill bit can be expected to drill 100 holes minimum to full depth in 4,000 psi concrete. The diameter of the bit required and the length of the bit. Tool drives 3/16” and 1/4” diameter tapcons. Eliminates the need for two drills or extra nut drivers. Using a socket wrench insert anchor into hole Tension strength design information for tapcon+ screw anchors1. Web when it comes to 3/8 tapcons, consider the drill bit size. Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. N single piece design—no nut and washer assembly. Also, consider the length of the tapcon screw when selecting a drill bit. Designed for use with a hammer drill and tapcon drill bits. Check the packaging or manufacturer’s instructions for more details. By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an accurate fit, thus obtaining higher tolerances for your concrete anchors. (see chart for socket size) (do not over tighten). Web how many pilot holes can i expect to get out of a tapcon drill bit? This size ensures a snug fit for the screw, allowing it to grip the masonry effectively and provide optimum holding power. N installs in less than half the time of a wedge anchor. These two dimensions should match the tapcon size in order to achieve the required holding values. Web the ideal drill bit size for a 5/16″ tapcon is generally a 1/4″ bit. A straight shank tapcon drill bit can be expected to drill 60 holes minimum to a 2 depth in 4,000 psi concrete. Web makes installation of tapcon® concrete anchors easy, fast, and accurate.10 Best Tapcon Drill Bit Chart In 2022 The Wrench Finder

Tapcon Size Chart A Visual Reference of Charts Chart Master

Tapcon Drill Bit Sizes Chart

Tapcon Drill Bit Sizes Chart

Tapcon Drill Bit Sizes Chart

Tapcon Bit Size Chart

Tapcon Bit Size Chart

Tapcon Drill Size Chart Printable Templates Free

Charts Yard and Garden Guru

Tapcon Bit Size Chart

N Use Standard Drill Bit Sizes.

There Are Numerous Technical Specifications That Must Be Considered When Using Tapcon® Screws.

Use The Tapcon Bits And Condrive Pro Together To Install Tapcon Anchors For Optimal Performance.

Using An Electric Impact Wrench, Or Socket Wrench (Hand Install) Insert Anchor Into Hole And Tighten Anchor Until Fully Seated.

Related Post: