Tig Welding Aluminum Settings Chart

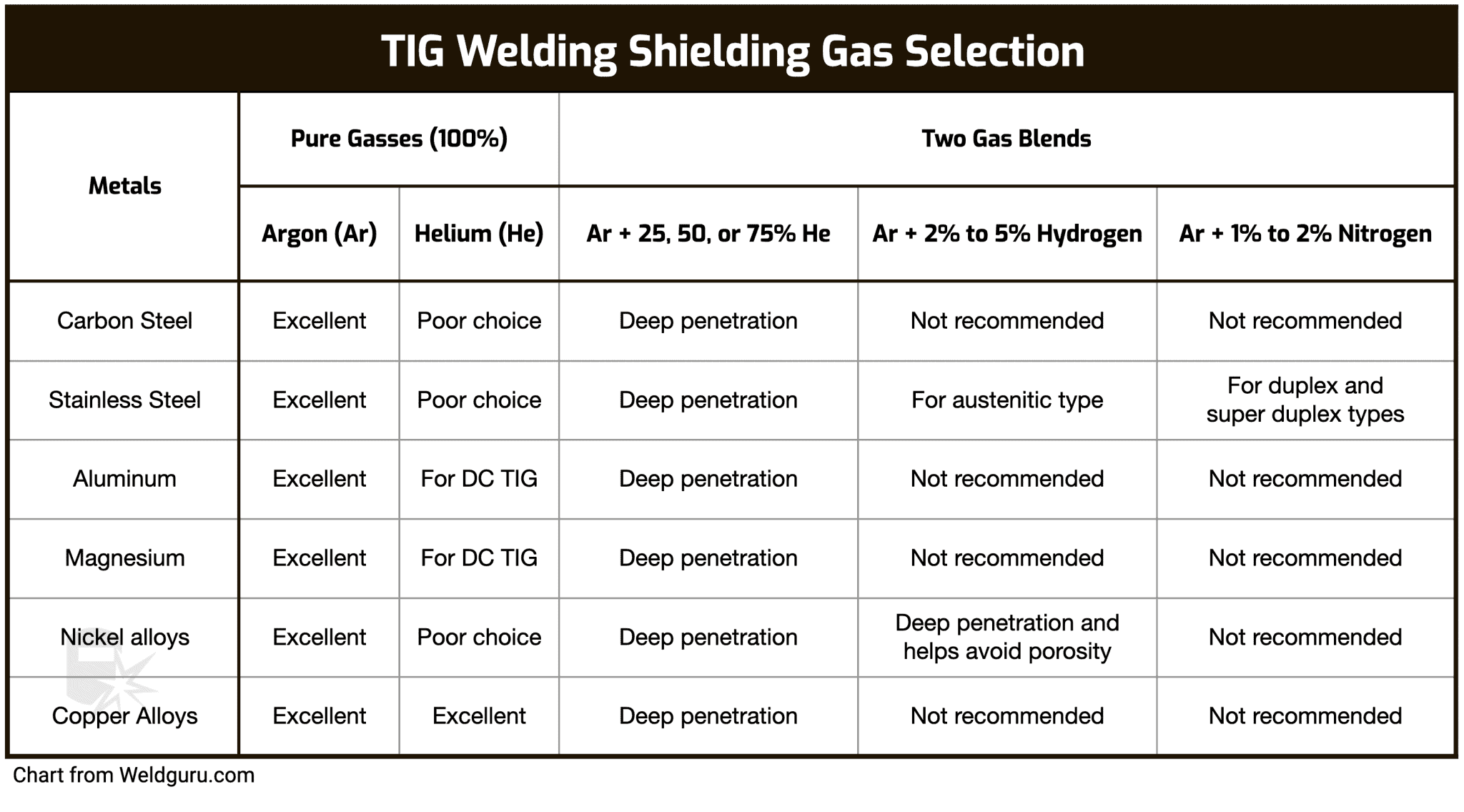

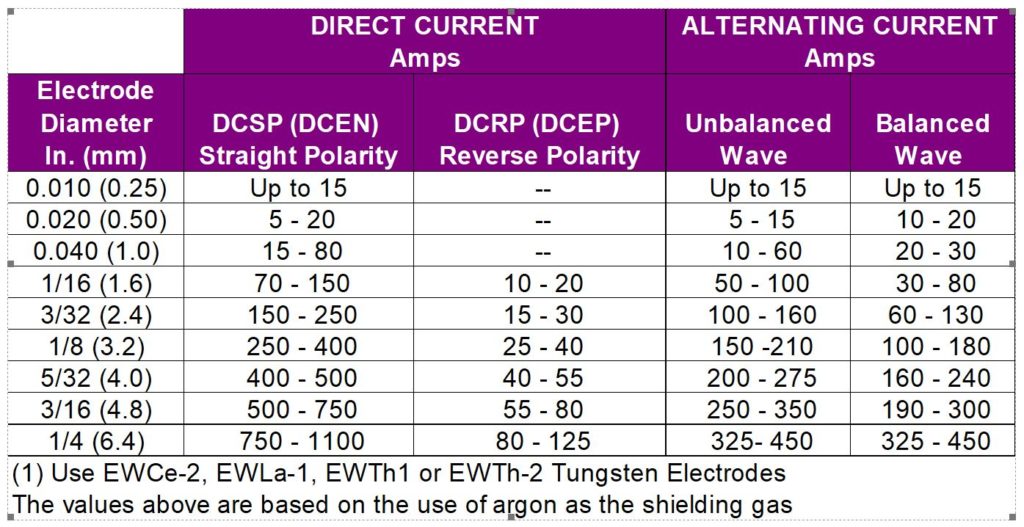

Tig Welding Aluminum Settings Chart - Web i have three charts here, all from the same source (ck worldwide technical specifications for tig welding), but they seem to contradict everything i've heard. This chart typically displays a range of settings for different materials, thicknesses, and welding positions. 141k views 2 years ago. The gas flow rate is crucial to ensure the joint's durability, integrity, and quality. This oxide film can inhibit the metal from flowing together to make a weld. Higher frequency settings are helpful when welding in tight areas or where more precision is needed. The aluminum settings require you to use pure tungsten or thoriated tungsten with a green, red and yellow band. Tap the bottom row buttons. Web the article provides a detailed guide on how to tig weld aluminum, covering aspects such as equipment setup, electrode selection, and technique. Web a flow of 15 to 25 cfh will cover most applications. Web settings for tig welding aluminum. Very large cup sizes will require more flow, but for the apprentice using about 20 cfh is sufficient. Gas flow rates for tig welding. You’ll do most tig welding of aluminum with ac at high frequency. Best tig welder for aluminum. Before getting started, there are a few important settings you need to understand and adjust, including the current, gas flow rate and amperage. Web the higher the setting, the tighter and more focused the arc becomes. Web 1 basics of tig welding aluminum; There is a wide range of settings you can use for welding aluminum. When tig welding aluminum, making some adjustments to your weld settings, like balance and frequency, can make a. There is a wide range of settings you can use for welding aluminum. There are many small differences and variables,. Tap the bottom row buttons. Web in addition to properly controlling heat, consider these seven tips to optimize results when welding aluminum with gtaw. Do you tig weld aluminum on ac or dc? 2 what parameters are important in tig welding? Travel speed (ipm) ac (amp) cup diameter (in) cup size. 6 ac or dc on aluminum; Web a flow of 15 to 25 cfh will cover most applications. Web 1 basics of tig welding aluminum; Web we'll talk about independent ac waveform control, gas selection, tig welding aluminum with dc tig, and techniques for welding anodized aluminum. 2 what parameters are important in tig welding? Web refer below chart for full tig aluminum setting for different base metal thicknesses. Web the tig welding parameters for aluminum are set forth in the table below. Gas flow. The gas flow rate is crucial to ensure the joint's durability, integrity, and quality. 22k views 3 years ago. An led green light will ensure you have the chosen option. Web empower your tig welding projects with our free online tig welding calculator. The exact settings will depend on the thickness of the material, the nature of the weld, and. There are many small differences and variables,. Gtaw welding equipment used for aluminum can be relatively complex and will contain a range of controls to adjust the welding waveform. The gas flow rate is crucial to ensure the joint's durability, integrity, and quality. 3 applications of tig welding with aluminum; Web a flow of 15 to 25 cfh will cover. Web the higher the setting, the tighter and more focused the arc becomes. From setup to troubleshooting, learn more about the basics of tig welding and get tips for tig welding success. 2 what parameters are important in tig welding? Web refer below chart for full tig aluminum setting for different base metal thicknesses. Web a flow of 15 to. Web we'll talk about independent ac waveform control, gas selection, tig welding aluminum with dc tig, and techniques for welding anodized aluminum. Do you tig weld aluminum on ac or dc? Web a flow of 15 to 25 cfh will cover most applications. According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel. Web for the best appearance, highest quality and leak free welds on aluminum, ac tig welding is the process of choice. Wonder what some of the most common settings i tinker with when i'm getting set up with tig welding aluminum?? 8 frequency suggestions for ac; When tig welding aluminum, making some adjustments to your weld settings, like balance and. Web aluminum settings for tig welding. Web by doug bates, handgun repair shop. 2 what parameters are important in tig welding? Web 1 basics of tig welding aluminum; Web we'll talk about independent ac waveform control, gas selection, tig welding aluminum with dc tig, and techniques for welding anodized aluminum. Before getting started, there are a few important settings you need to understand and adjust, including the current, gas flow rate and amperage. An led green light will ensure you have the chosen option. Very large cup sizes will require more flow, but for the apprentice using about 20 cfh is sufficient. Web empower your tig welding projects with our. It outlines the optimal settings based on material thickness and joint type. Lower settings give you a wider, flatter bead that is good for butt joints or areas that need to be built up with weld material. Do you tig weld aluminum on ac or dc? Web the higher the setting, the tighter and more focused the arc becomes. Web refer below chart for full tig aluminum setting for different base metal thicknesses. There is a wide range of settings you can use for welding aluminum. 3 applications of tig welding with aluminum; Web in addition to properly controlling heat, consider these seven tips to optimize results when welding aluminum with gtaw. Very large cup sizes will require more flow, but for the apprentice using about 20 cfh is sufficient. See also how to perform aluminum wheel welding safely and effectively. From setup to troubleshooting, learn more about the basics of tig welding and get tips for tig welding success. 141k views 2 years ago. Web we'll talk about independent ac waveform control, gas selection, tig welding aluminum with dc tig, and techniques for welding anodized aluminum. 6 ac or dc on aluminum; Web settings for tig welding aluminum. This oxide film can inhibit the metal from flowing together to make a weld.Aluminum Tig Welding Settings Chart

Tig Welding Charts For Aluminum

Aluminum Tig Welding Settings Chart

Tig Welding Aluminum Settings Chart

Tig Welding Settings Chart

Tig Welding Charts For Aluminum

TIG Welding Charts ILMO Products Company

Tig Weld Amp Chart

Aluminum Tig Welding Settings Chart

Aluminum Tig Rod Chart

You’ll Do Most Tig Welding Of Aluminum With Ac At High Frequency.

There Are Many Small Differences And Variables,.

The Primary Gas Used Is Argon And In Some Applications On Thick Aluminum When Additional Penetration.

Gtaw Welding Equipment Used For Aluminum Can Be Relatively Complex And Will Contain A Range Of Controls To Adjust The Welding Waveform.

Related Post: