Torch Tip Size Chart

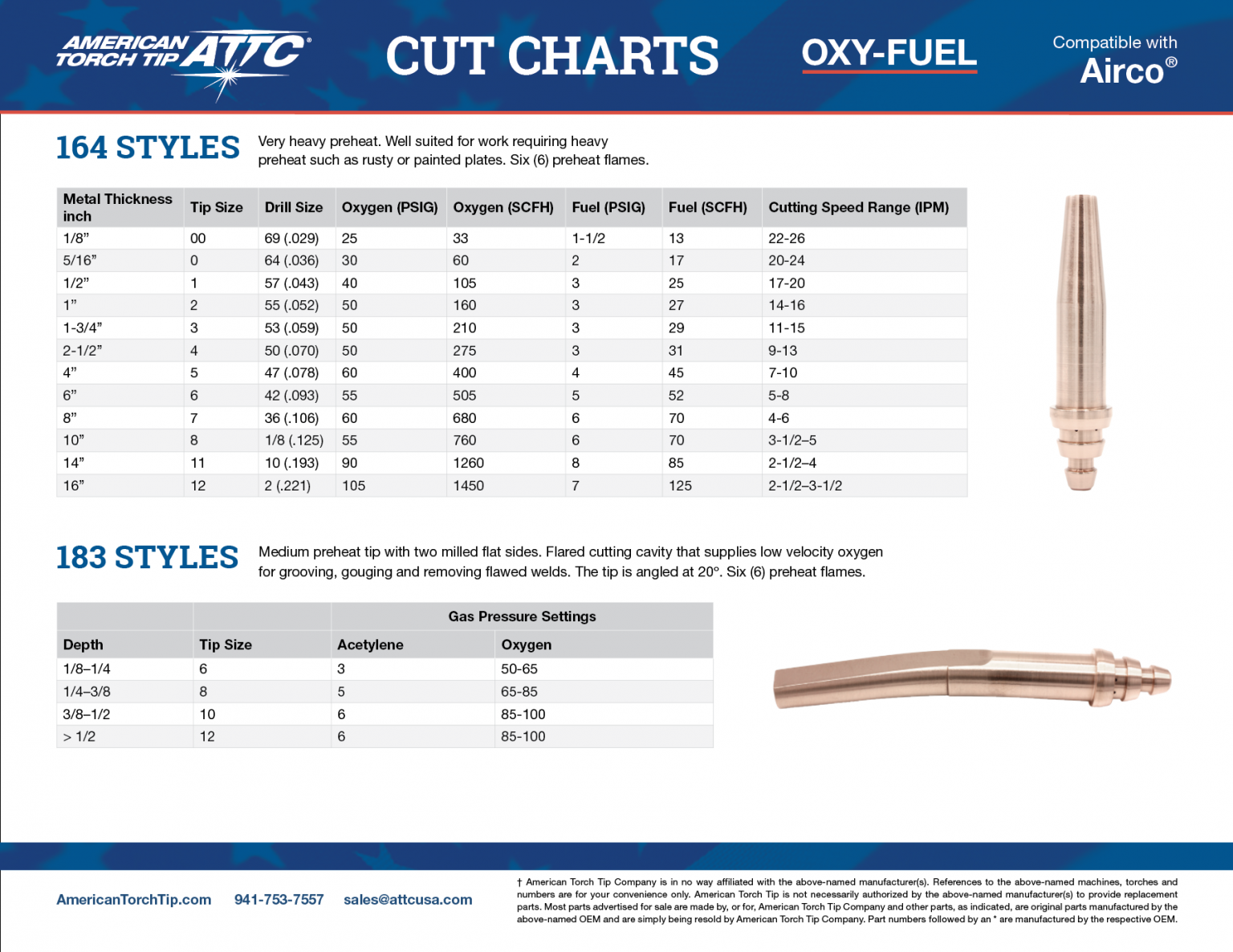

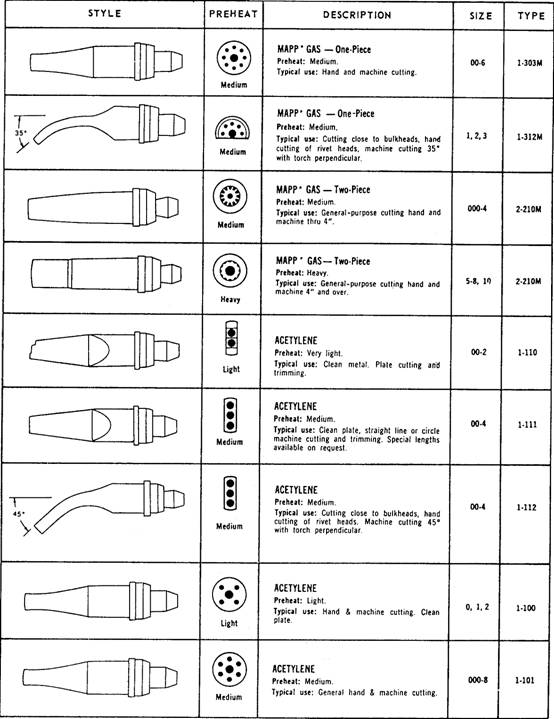

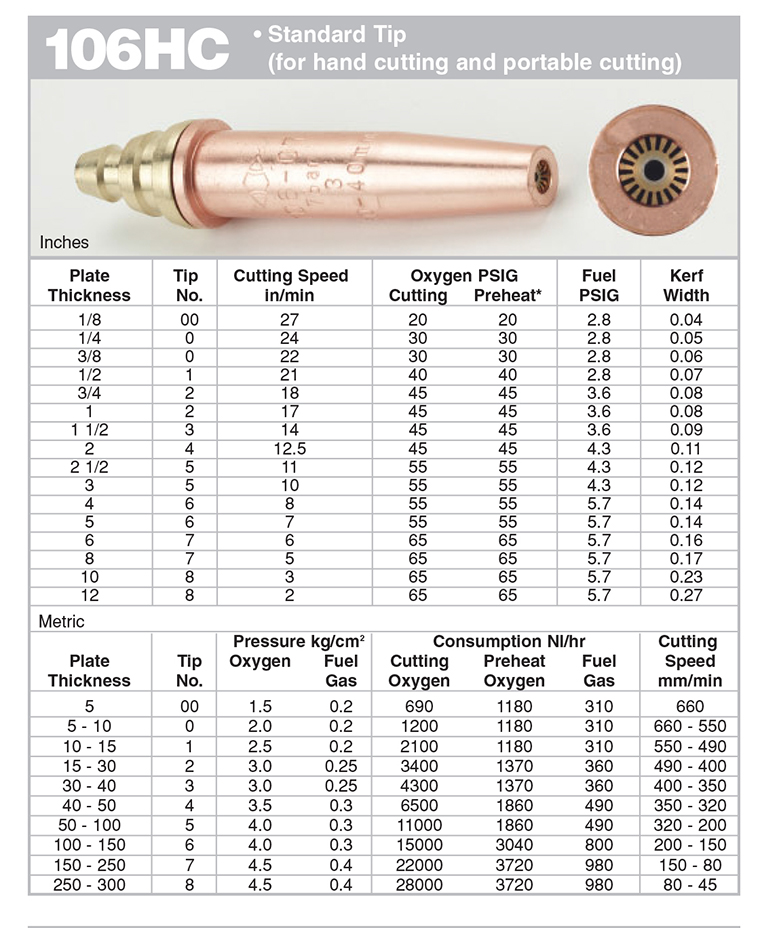

Torch Tip Size Chart - Web find the best tip size for cutting and welding different metals with acetylene, oxygen, fuel gas or mfa. Web learn how to identify and use the right torch tips for different fuel gases, processes, and materials. Use the charts below as recommended settings to use on your regulators for your cutting torch tips. See charts and examples of different tip sizes and. Web acetylene manifold system of sufficient size to supply the necessary volume. * applicable for three hose machine torch only. With a two hose cutting torch, preheat. Compare tip series, metal thickness, pressure, flow and speed data. **approximately 1470 gross btu per cubic foot. Join our community of over 20,000 industry experts and subscribe to our newsletters to. Web manufactured to meet the most rigid requirements of the metal fabrication industry, prostartm replacement tips are designed to fit the majority of the gas equipment. Web cutting torch tip flow charts. *use model hd310c torch and 3/8 hose. Determine the metal thickness you want to cut. With a two hose cutting torch, preheat. Web learn how to identify and use the right torch tips for different fuel gases, processes, and materials. Web acetylene manifold system of sufficient size to supply the necessary volume. Web ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web here are the tips: Web determine the manufacturer and model number of the cutting torches and/or cutting attachments being used. Join our community of over 20,000 industry experts and subscribe to our newsletters to. See charts and examples of different tip sizes and. **for best results use st 1600c / st 1900c or st 2600fc series torches and 3/8 hose when using tip size 6 or larger. This guide will walk you through the process and factors to consider for. Determine the thicknesses of steel to be cut. This guide will walk you through the process and factors to consider for optimal brazing results. Web • hand and machine torch cutting data compiled using mild steel as test material. Web ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web use. Web determine the manufacturer and model number of the cutting torches and/or cutting attachments being used. Determine the thicknesses of steel to be cut. * applicable for three hose machine torch only. Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip or torch damage. Web here. Web learn how to choose the right cutting torch tip for different metals, fuels, and preheat levels. Web cutting torch tip flow charts. Web here are the tips: Web ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Determine the thicknesses of steel to be cut. Determine the metal thickness you want to cut. Web cutting torch tip flow charts. Web determine the manufacturer and model number of the cutting torches and/or cutting attachments being used. The tip size is based on the cutting oxygen gas orifice. Select the tip size rated to cut that thickness or beyond. Web acetylene manifold system of sufficient size to supply the necessary volume. **approximately 1470 gross btu per cubic foot. With a two hose cutting torch, preheat. Web find the best tip size for cutting and welding different metals with acetylene, oxygen, fuel gas or mfa. Web determine the manufacturer and model number of the cutting torches and/or cutting attachments being. Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip or torch damage. *use model hd310c torch and 3/8 hose. Select the tip size rated to cut that thickness or beyond. Web find the best tip size for cutting and welding different metals with acetylene, oxygen, fuel. Hose for size 4 and larger. Compare tip series, metal thickness, pressure, flow and speed data. Web harris cutting tip charts. Web airco 144 / 164 / 183 / 263 cut chart. ** to provide required flow, use 3/8 i.d. * applicable for three hose machine torch only. Join our community of over 20,000 industry experts and subscribe to our newsletters to. Web learn how to choose the right cutting torch tip for different metals, fuels, and preheat levels. With a two hose cutting torch, preheat. Web acetylene manifold system of sufficient size to supply the necessary volume. Web use this quick and easy guide to help you select the most suitable tip for your smith little torch or silversmith torch. Web here are the tips: Compare tip series, metal thickness, pressure, flow and speed data. Determine the thicknesses of steel to be cut. *use model hd310c torch and 3/8 hose. With a two hose cutting torch, preheat. Web airco 144 / 164 / 183 / 263 cut chart. Web cutting torch tip flow charts. Web acetylene manifold system of sufficient size to supply the necessary volume. **for best results use st 1600c / st 1900c or st 2600fc series torches and 3/8 hose when using tip size 6 or larger. Fast shippingread ratings & reviewsdeals of the dayshop best sellers Web looking to select the perfect tip size for your brazing torch? ** to provide required flow, use 3/8 i.d. Use the charts below as recommended settings to use on your regulators for your cutting torch tips. Web cutting tip series gpn, hpn. Web choosing the right tip for your application will provide smoother cuts, protect you and your torch, and eliminate any downtime from tip or torch damage.Welding, Brazing Tip w/ Gas Mixer Style W1 ArcZone

Victor Tip Size Chart Printable Templates Free

Victor Cutting Torch Tip Chart

Welding Cut Charts American Torch Tip Cut Charts

Smith Cutting Torch Tip Chart

Oxy Acetylene Torch Tip Chart

Cutting Torch Guide

Victor Torch Welding Tip Chart Best Picture Of Chart

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

* Applicable For Three Hose Machine Torch Only.

Torches With Flashback Arrestors Require Up To 25% More Pressure As Tip Size.

Web Harris Cutting Tip Charts.

The Tip Size Is Based On The Cutting Oxygen Gas Orifice.

Related Post: