Weld Rod Chart

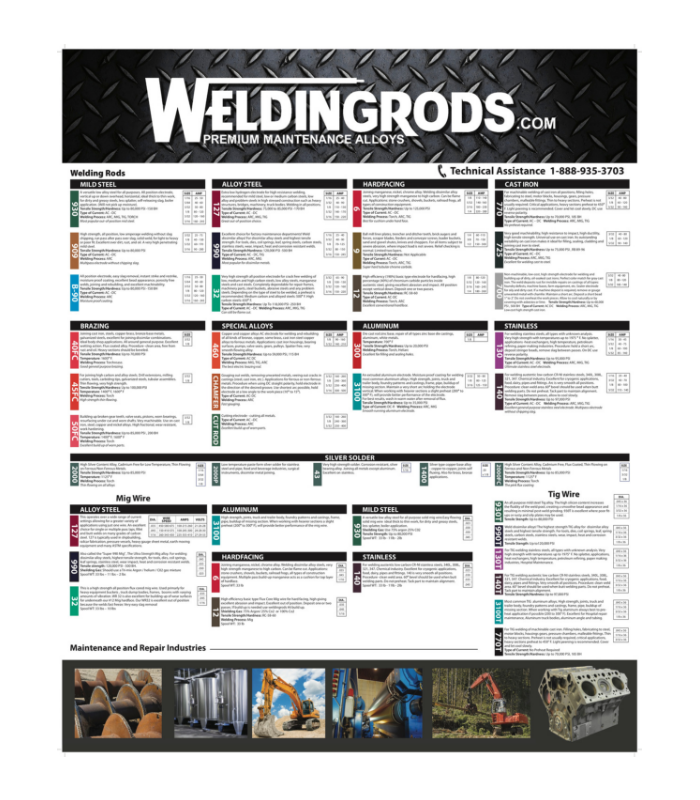

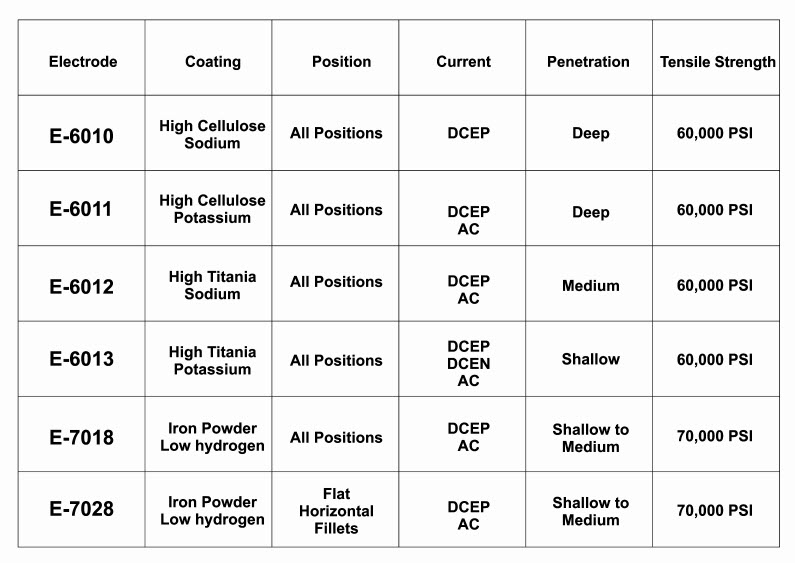

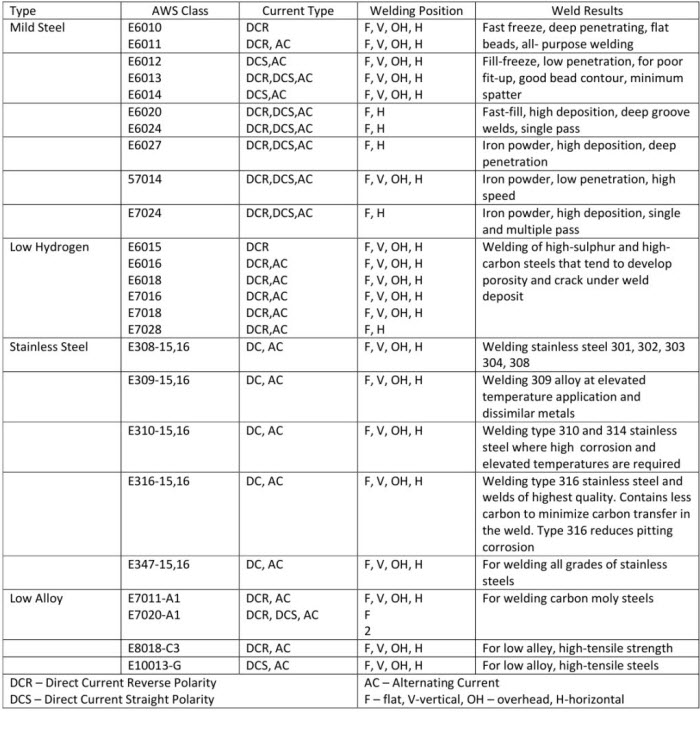

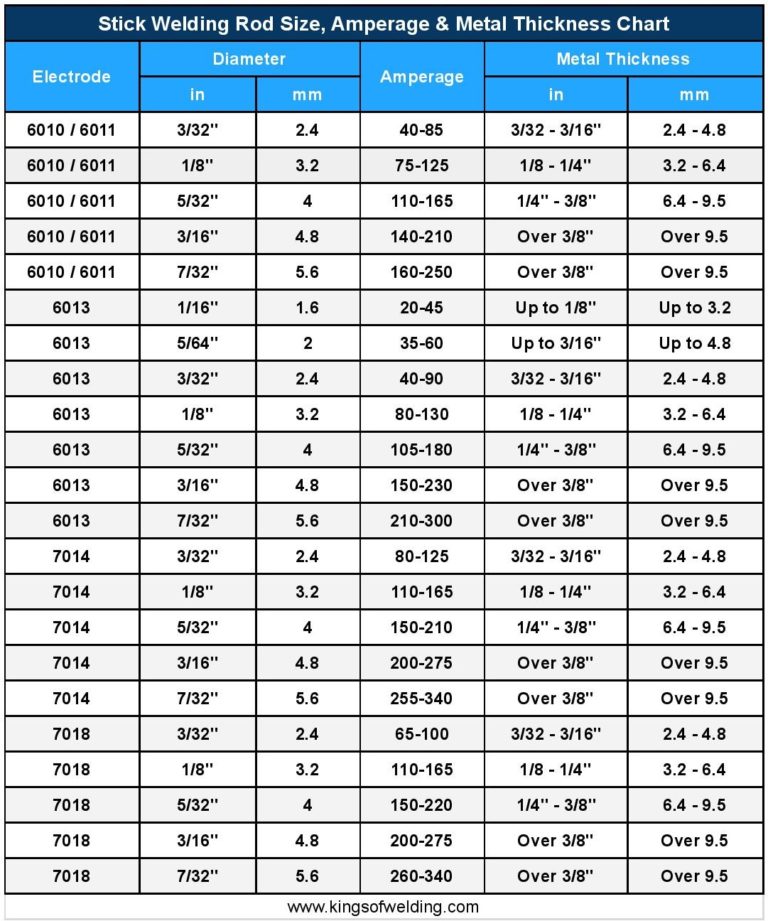

Weld Rod Chart - Web looking for a welding electrode and filler wire selection chart? Plus a chart with rod size and amperage per metal thickness in inches and mm. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. Discover the key factors to consider, such as base metal compatibility, welding position, and desired mechanical properties when choosing the right filler wire or. The numbers represent the pounds per square inch (psi) that the. Web how to choose the right welding rod size. Below is a chart that will give you a starting point for choosing the correct welding rod size. The table is published in aws a5.1 specification. We have gone into this in more detail below. This is accomplished by passing electric current from the welding. Contents [ show] common stick welding rods. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. Web the most common rods in welding are 7018, 7014, 6013, 6011, and 6010. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). You can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. In this guide, we’ll focus on which electrodes to use for mig/tig and stick welding. Web looking for a welding electrode and filler wire selection chart? The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. In this guide, we’ll focus on which electrodes to use for mig/tig and stick welding. Web to help you identify the appropriate stick welding rod for your projects, refer to the stick welding rod size chart below. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Web below is. Web how to choose the right welding rod size. The most common type of covered electrode is the lincoln electric “e6010” rod that is made from cellulosic coating. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. Web welding rod sizes with amperage chart. Web to help. The table is published in aws a5.1 specification. What are the common sizes of tig welding rods? A welding electrode chart is your roadmap. This is accomplished by passing electric current from the welding. Web our powerful calculator let's you easily determine which stick electrode you need. Welding is the process of fusing two pieces of metals (also called workpiece) together. Contents [ show] common stick welding rods. Web how to select stick welding rod type, size, and amperage. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. The most common type of covered. Plus a chart with rod size and amperage per metal thickness in inches and mm. A welding electrode chart is your roadmap. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. Web to help you identify the appropriate stick welding rod for your projects, refer to the stick welding rod size. Using a 7018 rod as an example, you can determine the tensile strength of the rod by the first two numbers. A low carbon content means it. Web electrode, current and polarity. Web how to choose the right welding rod size. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes. For smaw process, weaving shall be 3 times core dia. Web welding rod sizes with amperage chart. Web to help you identify the appropriate stick welding rod for your projects, refer to the stick welding rod size chart below. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. Plus a. The table is published in aws a5.1 specification. Web looking for a welding electrode and filler wire selection chart? Download our comprehensive pdf chart to simplify your electrode and filler wire selection process for any material. Web different types and sizes of welding rod. Discover the key factors to consider, such as base metal compatibility, welding position, and desired mechanical. Using a 7018 rod as an example, you can determine the tensile strength of the rod by the first two numbers. Plus you'll get the most complete welding rod chart on the internet in pdf! Web the most common rods in welding are 7018, 7014, 6013, 6011, and 6010. The electrode coating can help stabilize the arc, create smooth weld. Web welding electrode types, meaning, chart, table, uses, coating, size, symbols, numbers, classification, and defects. We have gone into this in more detail below. Web how to select stick welding rod type, size, and amperage. Web welding connects metals through heat and precision, and the right electrode is vital for a perfect bond. Welding is the process of fusing two. Contents [ show] common stick welding rods. Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. Web welding rod sizes with amperage chart. You can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. In this guide, we’ll focus on which electrodes to use for mig/tig and stick welding. The vertical up and overhead procedures in this section recommend 3/16” and smaller fleetweld 5p or 5p+ (e6010) electrode using electrode positive and currents in the lower portion of the electrode’s range. Discover the key factors to consider, such as base metal compatibility, welding position, and desired mechanical properties when choosing the right filler wire or. Web our powerful calculator let's you easily determine which stick electrode you need. Using a 7018 rod as an example, you can determine the tensile strength of the rod by the first two numbers. The most common type of covered electrode is the lincoln electric “e6010” rod that is made from cellulosic coating. Click here to see the welding rod chart in pdf format. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Below is a chart that will give you a starting point for choosing the correct welding rod size. Web how to select stick welding rod type, size, and amperage. Web welding connects metals through heat and precision, and the right electrode is vital for a perfect bond.Welding Rod Chart

Thickness Welding Rod Sizes Chart

Lincoln Welding Rod Chart

Welding Rod Chart

Arc Welding Rods Guide

Hobart Welding Rod Chart

Arc Welding Rods Guide

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding

Stainless Steel Filler Rod Chart

Ac Welding Rod Chart

Web The Most Common Rods In Welding Are 7018, 7014, 6013, 6011, And 6010.

For Smaw Process, Weaving Shall Be 3 Times Core Dia.

Web In Stick Welding, The Welding Electrode Is Covered With A Flux That Helps Protect The Weld Puddle From Atmospheric Contamination And Aids In The Formation Of A Good Weld Bead.

Plus You'll Get The Most Complete Welding Rod Chart On The Internet In Pdf!

Related Post: