Welding Cable Diameter Chart

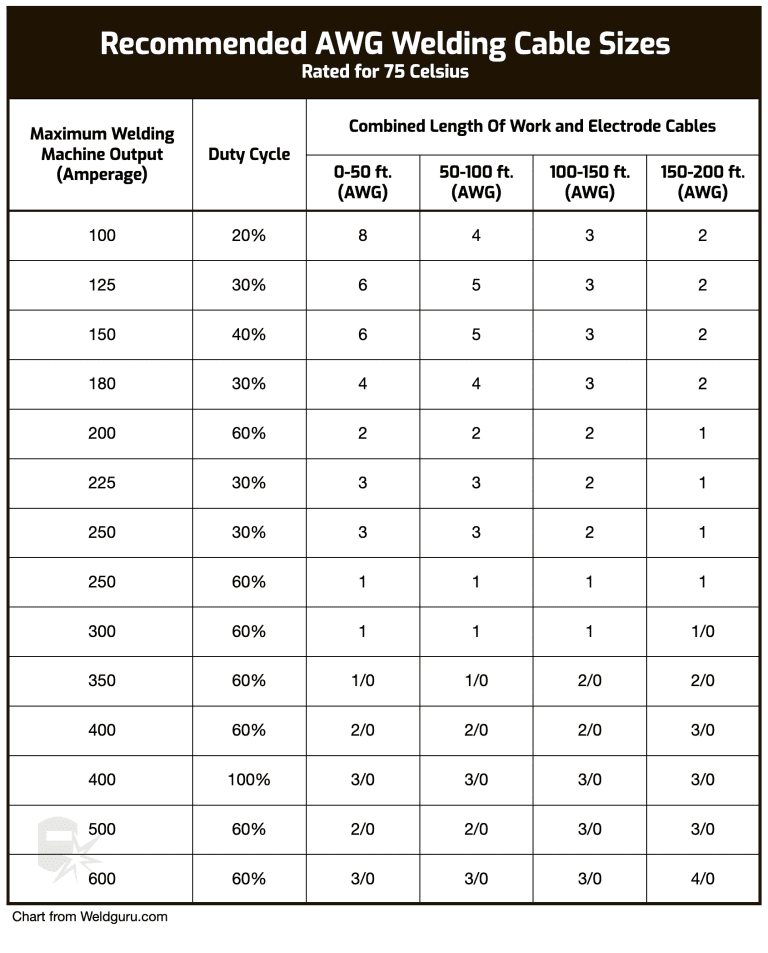

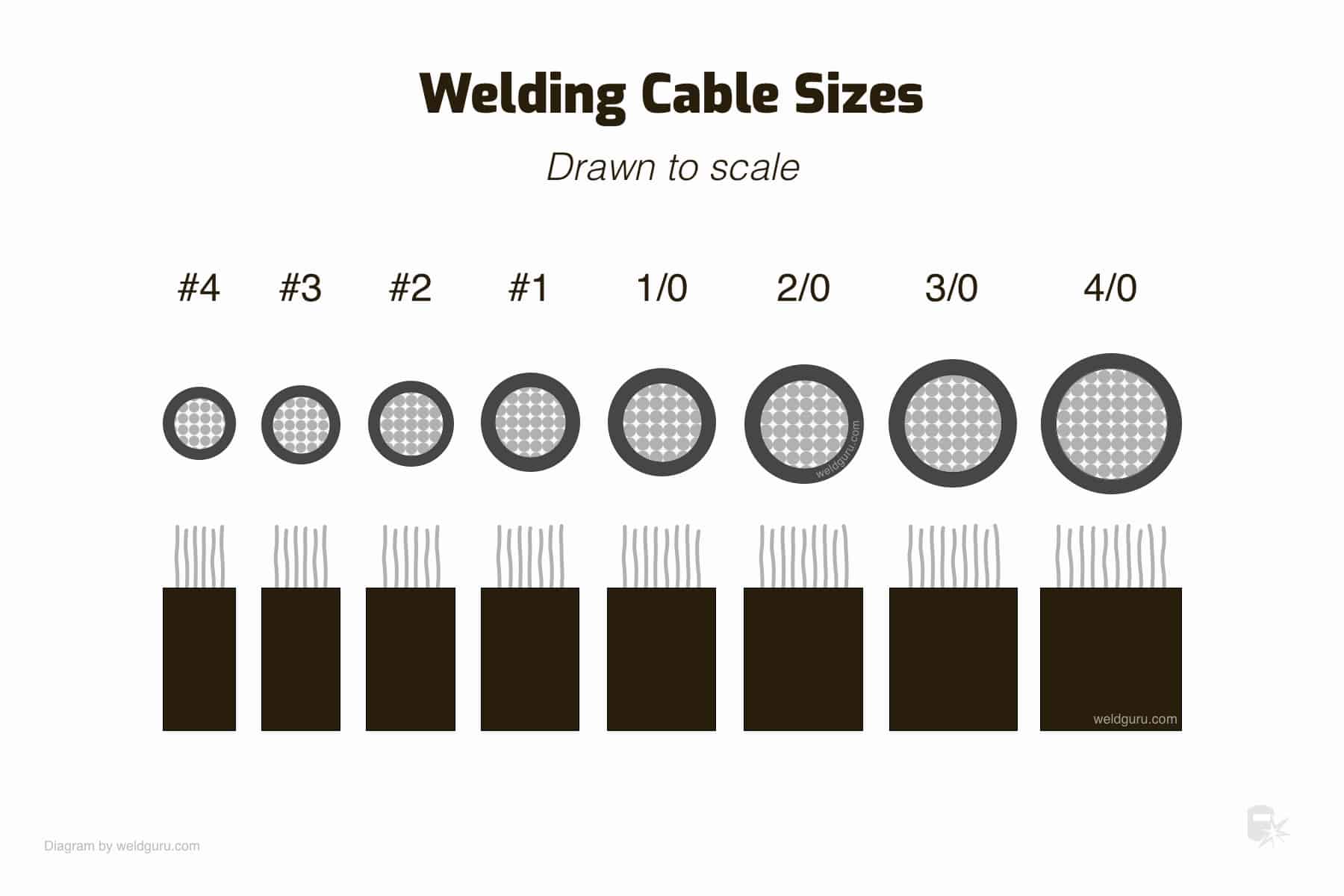

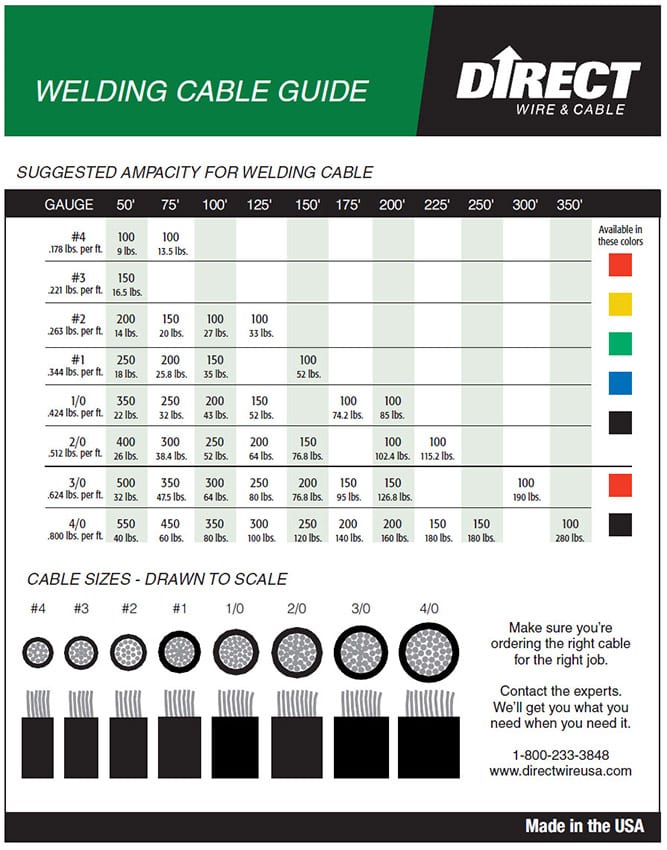

Welding Cable Diameter Chart - We carry a wide range of welding gas such as acetylene, co2, argon, mixtures, helium, specality, nitrogen, and oxygen. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Web cable sizes between #4 and #4/0 are typically used for welding cable. All types of welding wearable parts. How do we measure the welding cable sizes? Awg sizes will have three numbers, for example, 2 awg 625/30. Due to variables within welding applications, it is recommended the user consult an electrical engineer for a particular welding application. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. The wire acts as the filler material that melts and joins metal pieces together during welding. Web choosing the right size welding cables is important because you don’t want your machine to work improperly or catch fire. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Web for thicker materials use a larger wire diameter and larger machine, check the recommended welding capability of you machine. Due to variables within welding applications, it is recommended the user consult an electrical engineer for a particular welding application. As a guide refer to the “welding wire thickness chart” below. Quick guide to selecting the right welding cable sizes. Welding cable size is measured by the american wire gauge (awg) standard. Selecting the appropriate mig wire size is crucial for successful welding. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. To ensure your welding project works without a hitch, you should know your way around welding cables. Other steel fabricated products include flotation pontoons for dredging operations, large diameter welded pipe, duct work, bins and hoppers. Web the first is the wire diameter, which is usually given in thousands of an inch. Risks of incorrect cable size. Awg sizes will have three numbers, for example, 2 awg 625/30. If you're looking for welding service provider in orlando, fl, make sure to hire the professionals from s & g mobile welding. It includes the gauge, length, and. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Risks of incorrect cable size. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating. For example, a higher number refers to a smaller diameter cable, while more prominent lines are. Web the first is the wire diameter, which is usually given in thousands of an inch. Luckily, a standardized size chart using american wire gauge sizing tells you which size to. The most common sizes for welding on sheet metal are 0.35 and 0.45. Distance from power source (per lead). We carry a wide range of welding gas such as. The work cable attaches to a work clamp. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. The most common sizes for welding on sheet metal are 0.35 and 0.45. The wire acts as the filler material that melts and joins metal pieces together during welding.. Web for thicker materials use a larger wire diameter and larger machine, check the recommended welding capability of you machine. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract. To ensure your welding project works without a hitch, you should know your way around welding cables. Web in this article, we’ll navigate the key points,. Utilize a cable size chart. Web for thicker materials use a larger wire diameter and larger machine, check the recommended welding capability of you machine. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract. Risks of incorrect cable size. The wire acts as the filler material that melts and joins metal pieces together during welding. Luckily, a standardized size chart using american wire gauge sizing tells you which size to. Awg sizes will have three numbers, for example, 2 awg 625/30. We carry a wide range of welding gas such as acetylene, co2, argon, mixtures, helium, specality, nitrogen, and oxygen. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. To. Wire and cable for every application. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating. Distance from power source (per lead). The work cable attaches to a work clamp. Risks of incorrect cable size. Understand your power source output. Web standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Wire and cable for every application. For shipboard items, please also visit seacoast. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Measure your welding circuit length. The most common sizes for welding on sheet metal are 0.35 and 0.45. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating. We carry a wide range of welding gas such as acetylene, co2, argon, mixtures, helium, specality, nitrogen, and oxygen. Distance. Wire and cable for every application. For example, a higher number refers to a smaller diameter cable, while more prominent lines are labeled with 1/0, 2/0, and higher. Web standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. Distance from power source (per lead). Web in order for a welding cable to be adequate for your specific setup, it must have an appropriate diameter. The right welding cable size will help your work, while the wrong one will give you some problems. Web choosing the right size welding cables is important because you don’t want your machine to work improperly or catch fire. The wire acts as the filler material that melts and joins metal pieces together during welding. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Web electrical cables are typically categorized by an awg (american wire gauge) size. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. Measure your welding circuit length. The work cable attaches to a work clamp. Web cable sizes between #4 and #4/0 are typically used for welding cable. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract.welding cable size chart pdf Wiring Diagram and Schematics

Welding Cable Size What's Best? (with Chart)

Welding Ground Cable Size Chart

Welding Cable Ampacity Chart

Welding Cable Size Guide Charts & Tips for the Right Choice

Welding Cable Wire Size Chart Welding Mania

Welding Cable Size What’s Best? (with Chart)

Welding Cable Size Chart

Welding Cable Size Chart

WeldingCableSizeAmperageChart Toll Gas & Welding Supply

How Do We Measure The Welding Cable Sizes?

Welding Cable Sizes Are Drawn To Scale.

Selecting The Appropriate Mig Wire Size Is Crucial For Successful Welding.

To Ensure Your Welding Project Works Without A Hitch, You Should Know Your Way Around Welding Cables.

Related Post: