X Bar Chart And R Chart

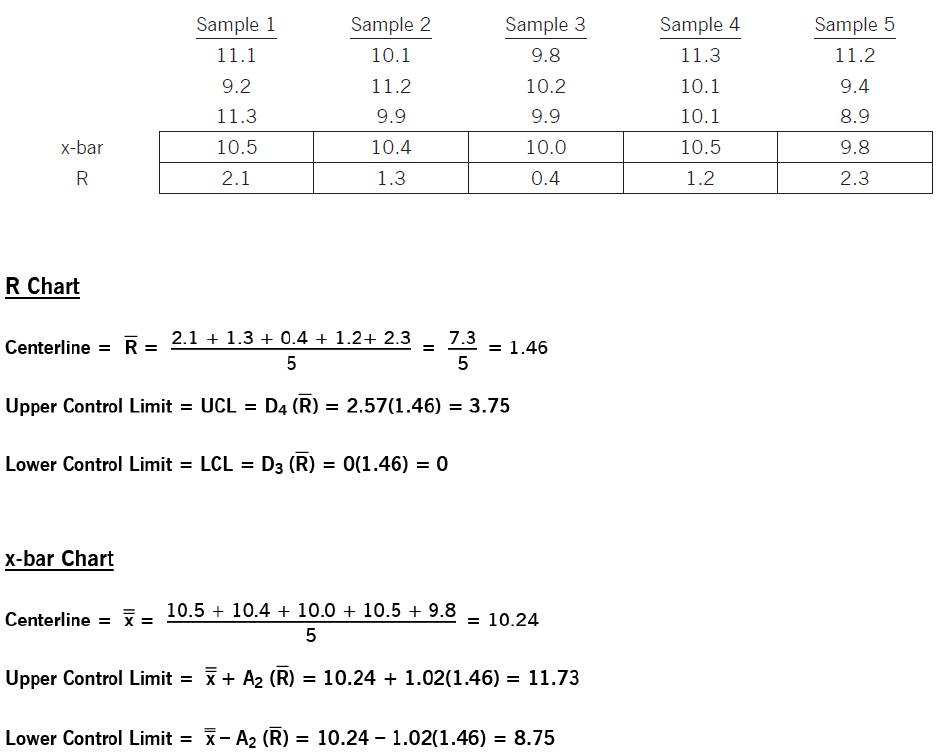

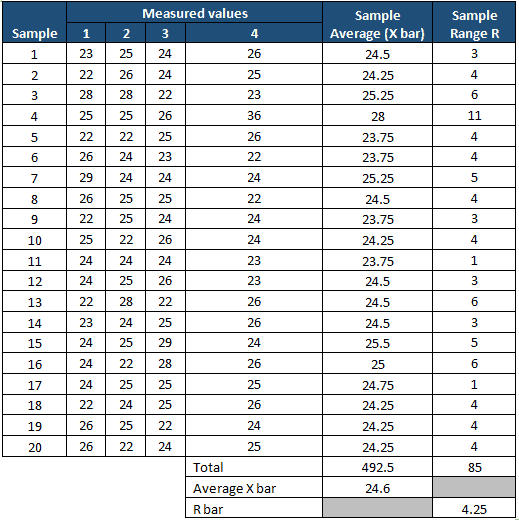

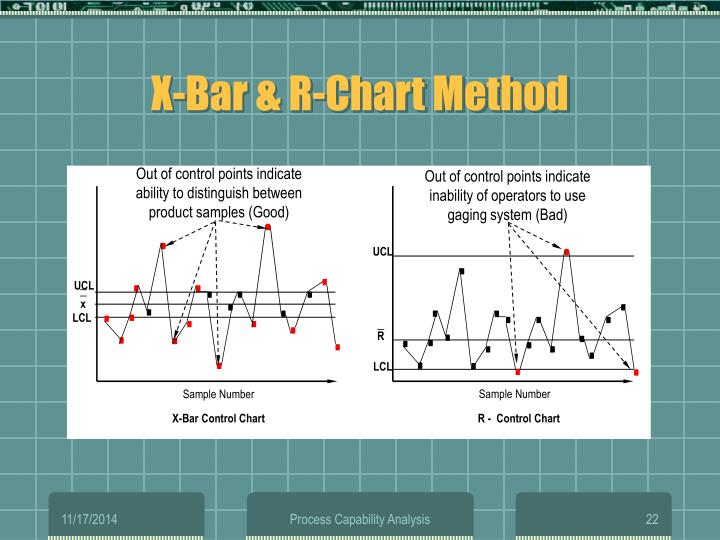

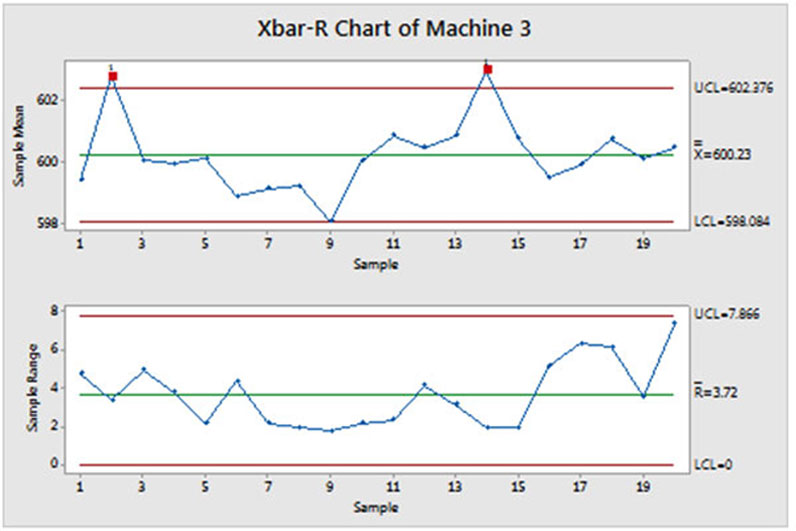

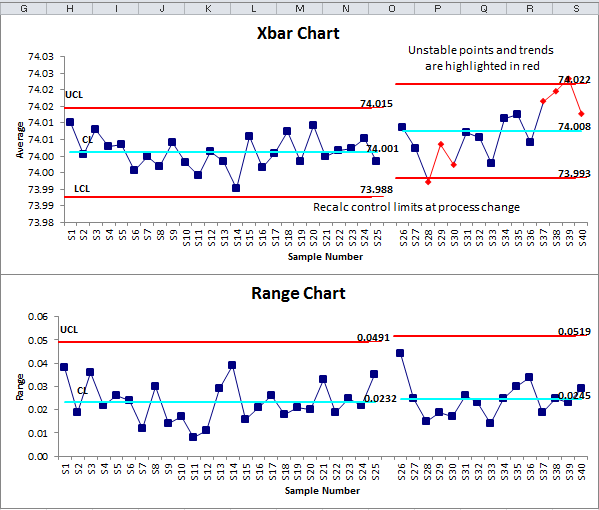

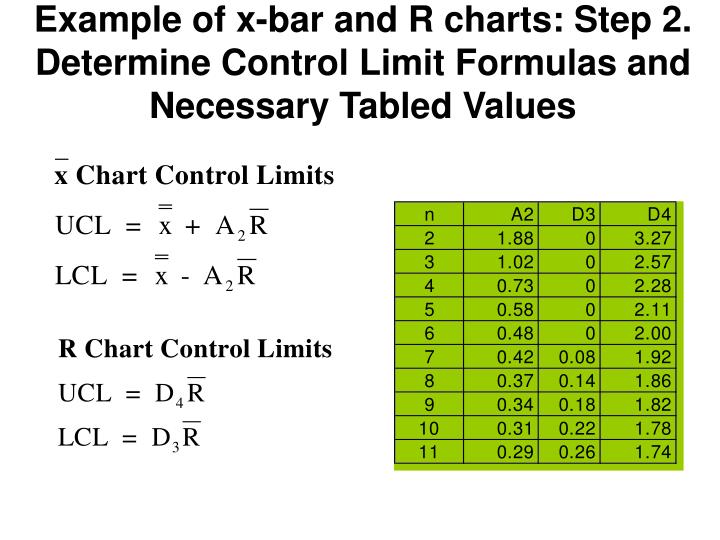

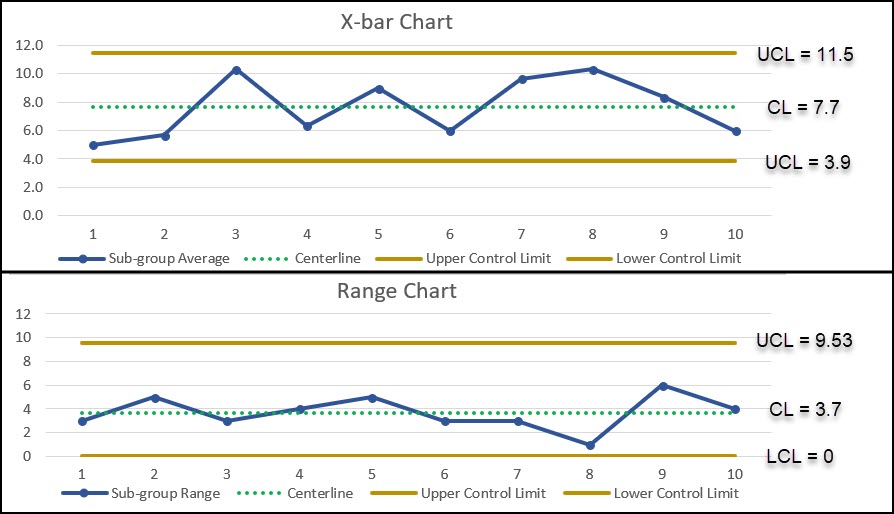

X Bar Chart And R Chart - Collect initial set of samples. Using the smart, intuitive system, these visual snapshots are just two clicks away. Web the xbar chart plots the average of the measurements within each subgroup. Web armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. Web xbar and r chart. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the process standard deviation. First the r chart is constructed. Consider the cost of sampling, required resources, and balance with minimizing time (and produced units) between measurements. The control limits on both chats are used to monitor the mean and variation of the process going forward. The center line is the average of all subgroup averages. Using the smart, intuitive system, these visual snapshots are just two clicks away. X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. Consider the cost of sampling, required resources, and balance with minimizing time (and produced units) between measurements. The center line is the average of all subgroup averages. Let’s do a simulation… so,. The control limits on both chats are used to monitor the mean and variation of the process going forward. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. If so, you most likely used some type of software package to display your data and compute the necessary control limits for your xbar and r chart. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. But, have you ever wondered how these control limits for an xbar and r. Web armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. Let’s do a simulation… so,. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the process standard deviation. These are used to monitor the effects of process improvement theories. The range of a sample. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the process standard deviation. Web what are x bar r control charts? Determine the sample size, n, and frequency of sampling. These are used to monitor the effects of process improvement theories. Let \(r_1, \, r_2, \, \ldots, r_k\), be. A simulation was developed to help do this. Let’s do a simulation… so,. The range of a sample is simply the difference between the largest and smallest observation. Web since we use the average range and the average standard deviation to compute the control limits for the xbar chart, then having a standard deviation that estimates the population best is. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the process standard deviation. Using the smart, intuitive system, these visual snapshots are just two clicks away. Web xbar and r chart.. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Let’s do a simulation… so,. Web armed with this background we can now. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the subgroup averages. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. Determine the sample size, n, and frequency of sampling. They provide continuous. If so, you most likely used some type of software package to display your data and compute the necessary control limits for your xbar and r chart. A simulation was developed to help do this. The range of a sample is simply the difference between the largest and smallest observation. Web the xbar chart plots the average of the measurements. X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the. Using the smart, intuitive system, these visual snapshots are just two clicks away. Web since we use the average range and the average standard deviation to compute the control limits for the xbar chart, then having a standard deviation that estimates the population best is critical. Of course, more samples and more frequent measurements is better statistically. They are a. X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. The range of a sample is simply the difference between the largest and smallest observation. The average range is $$ \bar{r} = \frac{r_1 + r_2. Let’s do a simulation… so,. Web the xbar chart plots the average of the measurements within each subgroup. These are used to monitor the effects of process improvement theories. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. The average range is $$ \bar{r} = \frac{r_1 + r_2 +. They are a standardized chart for variables data and help determine if a particular process is predictable and stable. $$ then an estimate of \(\sigma\) can be computed as $$ \hat{\sigma} = \frac{\bar{r}} {d_2} \,.$$ Web armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. Collect initial set of samples. Determine the sample size, n, and frequency of sampling. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. If the r chart validates that the process variation is in statistical control, the xbar chart is constructed. Consider the cost of sampling, required resources, and balance with minimizing time (and produced units) between measurements. But, have you ever wondered how these control limits for an xbar and r. The control limits on both chats are used to monitor the mean and variation of the process going forward. The center line is the average of all subgroup averages.How To Create an XBar R Chart Six Sigma Daily

X Bar R Control Charts

X Bar And R Chart

How To Plot Xbar And R Bar Chart In Excel Acetored vrogue.co

Difference Between XBar and RChart and How They Are Used ROP

X Bar R Chart Excel Average and Range Chart

Xbar and R Chart Formula and Constants The Definitive Guide

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

X Bar R Chart Example

Statistical Process Control (SPC) CQE Academy

First The R Chart Is Constructed.

Of Course, More Samples And More Frequent Measurements Is Better Statistically.

Web In Statistical Process Control (Spc), The ¯ And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed Variables Simultaneously, When Samples Are Collected At Regular Intervals From A Business Or Industrial Process.

A Simulation Was Developed To Help Do This.

Related Post: